The Ayrshire County Council House: A Comprehensive Guide for Home Buyers and Investors

Historical Context and Manufacturing Details

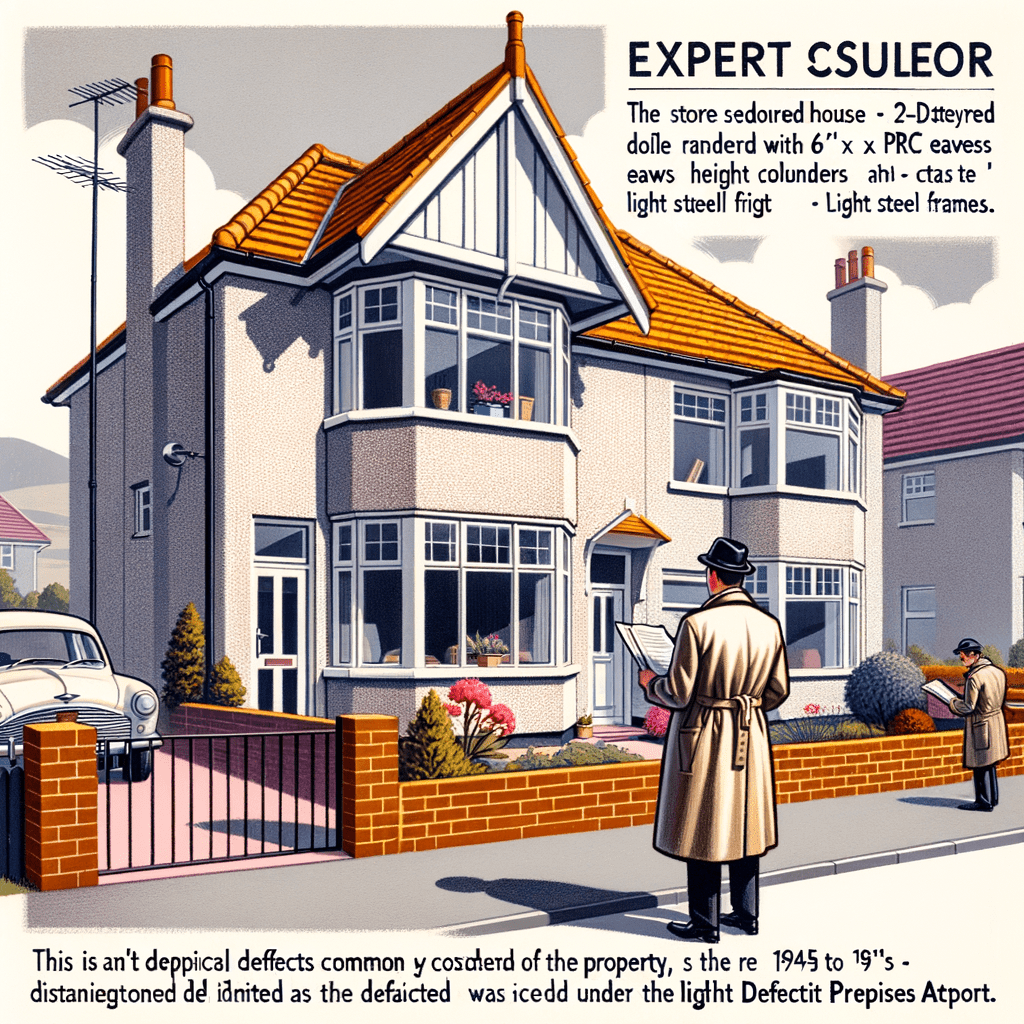

The Ayrshire County Council houses, a notable example of post-war British architecture, were constructed between 1945 and 1954. These properties were designed by the renowned architects RG Lindsay and W A Fairhurst. A total of 750 units were built during this period, primarily to address the acute housing shortage following World War II. These houses are predominantly found in Ayrshire, Scotland, and are a testament to the ingenuity and resourcefulness of the era.

The construction of these houses was part of a broader initiative to provide affordable and durable housing for the working class. The use of prefabricated reinforced concrete (PRC) was a revolutionary approach at the time, allowing for rapid construction and cost efficiency. However, this method also introduced certain challenges and risks that modern buyers and investors need to be aware of.

Identification Characteristics

Ayrshire County Council houses are typically two-storey semi-detached properties. They are easily identifiable by their steep pitch gable roofs covered with tiles and their external walls, which are rendered with roughcast throughout. These houses have a distinctive appearance that sets them apart from other post-war housing types.

Key Features:

- Roof: Steep pitch gable roof covered with tiles.

- External Walls: Rendered (roughcast) throughout.

- Structure: Two-storey semi-detached houses.

Construction Details

Understanding the construction details of Ayrshire County Council houses is crucial for potential buyers and investors. These properties were built using a combination of concrete pad foundations, PRC columns, and light steel frames. Here is a detailed breakdown of the construction elements:

Substructure:

- Foundations: Concrete pad foundations with a square rebate to receive column bases, concrete strip footings, and brick underbuilding with a damp-proof course (DPC).

Frame:

- Columns: 6″ x 6″ PRC eaves height columns, with those in the centre of the house jointed about 2′ 6″ above the first floor level.

- Beams: PRC perimeter beams joined to columns via reinforcing loops protruding from the rebated end of the beam and fixed to metal lugs protruding from the face of the column. Concrete cover to joint.

External Walls:

- Panels: Rendered storey-height 2″ foamed slag concrete panels, 2″ cavity, storey-height light steel frame tied to the external masonry leaf infilled with glass fibre insulation and lined with plasterboard.

Internal Walls:

- Separating Wall: 3″ foamed slag concrete slab cavity wall lined with plasterboard, with a 2″ cavity except where broken to permit the enclosure of the column halfway along the wall.

- Partitions: Light steel frame lined with plasterboard.

Floors:

- Ground Floor: Timber boarding on timber battens on PRC beams.

- First Floor: Timber boarding on timber battens on PRC beams.

Ceilings:

- Material: Plasterboard.

Roof:

- Structure: Light steel trusses, timber boarding, and tiles. Note that the steelwork was treated with stoved paint.

Typical Variants

While the standard Ayrshire County Council house follows the construction details outlined above, there are some variants that potential buyers should be aware of:

- External Walls: Some houses have external walls separately clad with rendered brick.

- Beam and Column Frame Joint: In some variants, there is no concrete infill to the beam and column frame joint.

- Inner Leaf of External Walls: Some houses have an inner leaf of external walls made of timber frame panels.

- Ground Floor: In certain variants, the ground floor is made of concrete.

- First Floor: Some houses have a first floor made of timber joists instead of PRC beams.

Typical Hazards and Risks

While Ayrshire County Council houses were innovative for their time, they come with certain hazards and risks that modern buyers need to consider. These properties are classified as defective under the Defective Premises Act, primarily due to issues related to the durability of the reinforced concrete used in their construction.

Common Defects:

- Corrosion of Steel in Concrete: Over time, the steel reinforcement within the concrete can corrode, leading to structural weaknesses. This is particularly problematic in areas with high moisture levels.

- Carbonation: The concrete can undergo a process called carbonation, which reduces its alkalinity and accelerates the corrosion of the steel reinforcement.

- Concrete Cover: The concrete cover to the joints between beams and columns can deteriorate, leading to exposure of the steel reinforcement and subsequent corrosion.

- Insulation Issues: The glass fibre insulation used in the external walls can degrade over time, leading to reduced thermal efficiency and potential damp issues.

Inspection and Assessment

When inspecting an Ayrshire County Council house, it is essential to conduct a thorough assessment of the reinforced concrete’s durability. The following resources provide valuable guidance on this matter:

- Corrosion of Steel in Concrete (BRE Digest 444, Parts 1–3)

- Repair and Maintenance of Reinforced Concrete (BR 254)

- Carbonation Depths in Structural-Quality Concrete (BR 19)

Inspection Checklist:

- Foundation and Substructure:

- Check for signs of settlement or movement in the concrete pad foundations and strip footings.

-

Inspect the brick underbuilding for any signs of damp or deterioration.

-

Frame:

- Examine the PRC columns and perimeter beams for signs of cracking, spalling, or corrosion.

-

Check the joints between beams and columns for any signs of concrete cover deterioration.

-

External Walls:

- Inspect the rendered foamed slag concrete panels for cracks, spalling, or other signs of deterioration.

-

Check the cavity insulation for signs of degradation or dampness.

-

Internal Walls:

- Examine the separating wall and partitions for any signs of structural movement or dampness.

-

Check the plasterboard linings for cracks or other signs of damage.

-

Floors:

-

Inspect the ground and first floors for any signs of movement, sagging, or deterioration of the timber boarding and battens.

-

Roof:

- Check the light steel trusses and timber boarding for signs of corrosion or deterioration.

- Inspect the roof tiles for any signs of damage or displacement.

Maintenance and Repair

Maintaining and repairing an Ayrshire County Council house requires a thorough understanding of the construction materials and techniques used. Here are some key considerations:

Corrosion Protection:

- Steel Reinforcement: Apply corrosion inhibitors to the steel reinforcement to prevent further corrosion.

- Concrete Cover: Repair or replace deteriorated concrete cover to protect the steel reinforcement.

Carbonation Mitigation:

- Carbonation Depth Testing: Conduct regular testing to monitor the depth of carbonation in the concrete.

- Surface Treatment: Apply surface treatments to the concrete to reduce carbonation rates.

Insulation Upgrades:

- Cavity Insulation: Replace degraded glass fibre insulation with modern, more efficient materials.

- Damp Proofing: Ensure that the cavity insulation is adequately protected against dampness.

Structural Repairs:

- Crack Repair: Repair any cracks in the concrete panels, columns, or beams using appropriate techniques and materials.

- Joint Reinforcement: Strengthen the joints between beams and columns to ensure structural integrity.

Conclusion

Ayrshire County Council houses are a unique and historically significant type of property that offers both opportunities and challenges for modern buyers and investors. Understanding the construction details, typical hazards, and necessary maintenance and repair strategies is crucial for making an informed decision.

At Flettons, we’re committed to safeguarding your investment. When considering a property purchase, trust our seasoned expertise to reveal any hidden threats. For a thorough building survey, get your instant quote through our quote calculator or reach out directly at 0203 691 0451. Your home’s safety is our top priority.