The Bates 4L House: A Comprehensive Guide for Home Buyers and Investors

Introduction to the Bates 4L House

The Bates 4L house, also known as the 4L, is a distinctive type of system-built property that emerged in the UK during the 1960s and 1970s. Designed by T Bates & Sons and manufactured by Four L (UK) Ltd, these properties were part of a broader movement towards prefabricated housing solutions aimed at addressing the post-war housing shortage. With approximately 830 units built, the Bates 4L house remains a notable example of mid-20th-century British architecture.

In this article, we will delve into the various aspects of the Bates 4L house, including its construction, typical characteristics, potential hazards, and considerations for prospective buyers and investors. Whether you are a seasoned property investor or a first-time homebuyer, understanding the intricacies of this property type is crucial for making informed decisions.

Historical Context and Manufacturing Details

Period of Construction

The Bates 4L houses were constructed between the 1960s and 1970s, a period marked by a significant demand for affordable and quickly constructed housing. The post-war era saw a surge in the development of system-built properties, which were designed to be assembled rapidly using prefabricated components.

Manufacturers and Designers

The Bates 4L house was a collaborative effort between T Bates & Sons, the designers, and Four L (UK) Ltd, the manufacturers. This partnership aimed to create a housing solution that was both cost-effective and efficient to build. The use of prefabricated reinforced concrete (PRC) panels and other innovative construction techniques allowed for the rapid assembly of these homes.

Number Built and Typical Locations

Approximately 830 Bates 4L houses were built during the construction period. These properties are typically found in suburban areas across the UK, where there was a high demand for affordable housing. The design and construction methods used in the Bates 4L house made it a popular choice for local authorities and housing associations looking to address the housing shortage.

Characteristics of the Bates 4L House

Identification Characteristics

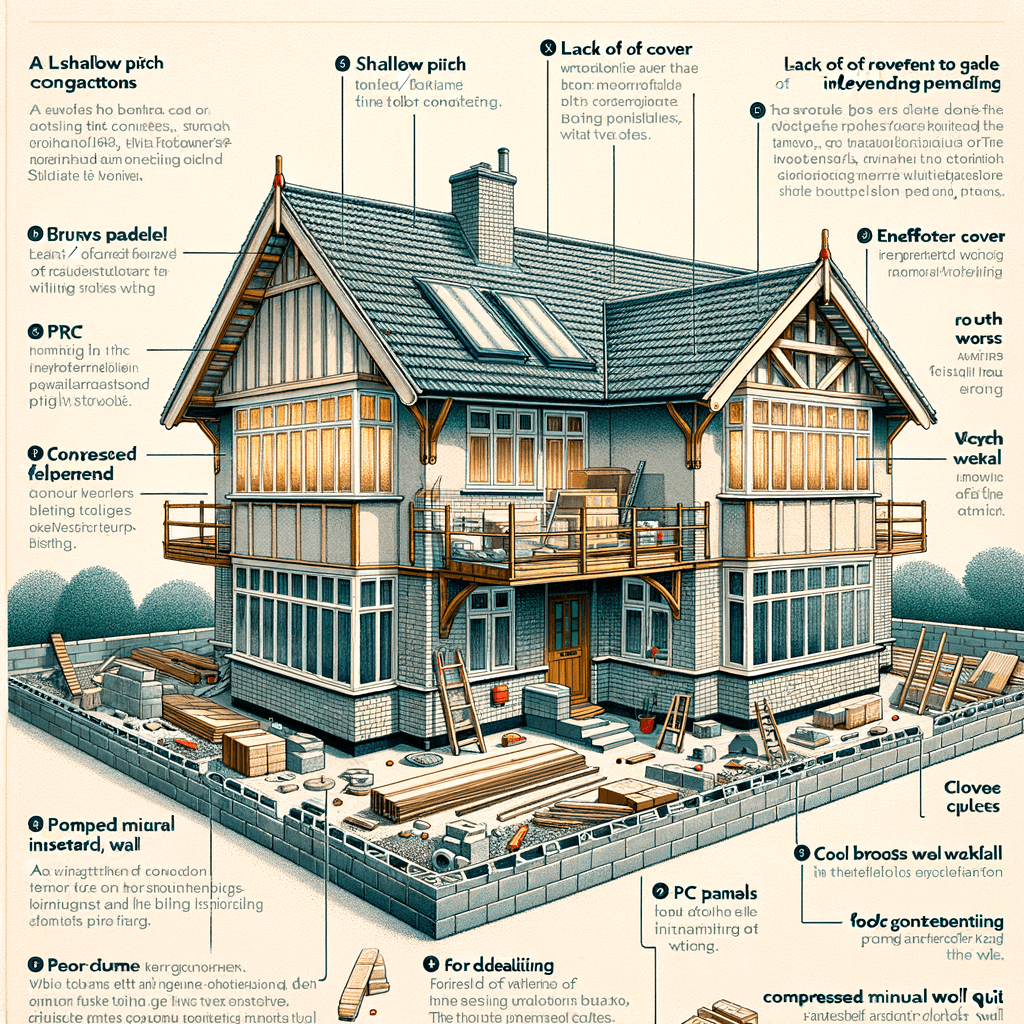

The Bates 4L house is a two-storey terraced property with several distinctive features that make it easily identifiable:

- Roof: The house has a shallow pitch gable roof covered with interlocking concrete tiles.

- External Walls: The external walls are constructed using Coloroc PC or pressed concrete cladding panels. In some cases, the walls are rendered throughout or to the first-floor level with horizontal timber boarding and horizontal shiplap plastic weatherboarding. Asbestos cement slates may also be used above the first floor.

- Agrément Board Certificate: The Bates 4L house is referenced in the Agrément Board Certificate NBA Certificate 1977, which provides further details on its construction and performance.

Typical Construction Details

Understanding the construction details of the Bates 4L house is essential for identifying potential issues and assessing the overall condition of the property. Here are the key construction elements:

Substructure

- Concrete Pads: The substructure consists of concrete pads located at the corners, midway along the front and rear walls, and at the centre of the ground floor slab.

- Concrete Underbuilding: The concrete underbuilding provides additional support to the structure.

- Ventilation Grill: Ventilation grills are installed to ensure proper airflow and prevent moisture buildup.

- Damp Proof Course (DPC): A DPC is included to prevent rising damp from affecting the structure.

External Walls

- PRC Ground Beam: The external walls are supported by a 120 mm x 170 mm PRC ground beam.

- PC Panels: The walls are constructed using 80 mm storey height PC panels and 100 mm storey height PRC corner panels.

- Insulation: Compressed mineral wool quilt and polystyrene insulation are used to provide thermal efficiency.

- Cladding: The external walls are clad with Coloroc PC cladding panels, horizontal shiplap plastic boarding, or asbestos cement slates.

Separating Wall

- PRC Panel Cavity Wall: The separating wall between properties is constructed using storey height PRC panel cavity walls.

Partitions

- Honeycomb Plasterboard: Internal partitions are made using honeycomb plasterboard, which provides a lightweight and cost-effective solution.

Floors

- Ground Floor: The ground floor consists of 80 mm PC slabs bolted to the PRC panels.

- First Floor: The first floor is constructed using PC slabs with grouted and welded connections.

Ceilings

- Plasterboard on Timber Joists: Ceilings are made of plasterboard mounted on timber joists, supported at mid-span by steel stanchions.

Roof

- Timber Trusses and Purlins: The roof structure includes timber trusses and purlins, a timber lattice ridge girder, and interlocking concrete tiles.

Variants

There are several variants of the Bates 4L house, which may feature different external wall claddings, such as render on expanded mesh, horizontal timber boarding, or PC cladding on DPC and soakers.

Typical Hazards and Risks

Lack of Cover to Reinforcement in PRC Panels and Ground Beams

One of the primary concerns with the Bates 4L house is the lack of adequate cover to the reinforcement in PRC panels and ground beams. This can lead to corrosion of the reinforcement, which in turn can compromise the structural integrity of the property.

Poor Detailing of Truss/Wall and Floor Beam/Wall Connections

Another common issue is the poor detailing of the connections between the trusses and walls, as well as the floor beams and walls. This can result in structural weaknesses and potential movement or settlement over time.

Asbestos-Containing Materials

Asbestos cement slates and other asbestos-containing materials were commonly used in the construction of Bates 4L houses. Asbestos poses significant health risks if disturbed, so it is essential to have a professional survey conducted to identify and manage any asbestos-containing materials.

Thermal Efficiency and Insulation

While the Bates 4L house includes some insulation materials, such as compressed mineral wool quilt and polystyrene insulation, these may not meet modern standards for thermal efficiency. Upgrading the insulation can improve energy efficiency and reduce heating costs.

Defective Premises Act and Bates 4L Houses

The Defective Premises Act 1972 imposes a duty on builders, developers, and landlords to ensure that properties are constructed and maintained to a reasonable standard. While the Bates 4L house was designed to meet the standards of its time, some of the construction methods and materials used may not comply with modern building regulations.

Classified as Defective

Due to issues such as the lack of cover to reinforcement and the use of asbestos-containing materials, Bates 4L houses may be classified as defective under the Defective Premises Act. This classification can impact the property’s value and mortgageability, so it is essential to have a thorough survey conducted before purchasing a Bates 4L house.

Inspection Tips for Bates 4L Houses

When inspecting a Bates 4L house, it is crucial to pay attention to specific areas that are prone to defects. Here are some tips for conducting a thorough inspection:

External Walls and Cladding

- Check for Cracks and Damage: Inspect the external walls and cladding for any cracks, damage, or signs of movement. Pay particular attention to the PRC panels and ground beams.

- Assess Insulation: Evaluate the condition of the insulation materials, such as compressed mineral wool quilt and polystyrene insulation. Upgrading insulation may be necessary to improve thermal efficiency.

Roof and Trusses

- Inspect Roof Covering: Examine the interlocking concrete tiles for any signs of damage or wear. Ensure that the roof covering is intact and provides adequate protection against the elements.

- Check Truss Connections: Assess the connections between the timber trusses and walls for any signs of poor detailing or structural weaknesses.

Floors and Ceilings

- Evaluate Floor Slabs: Inspect the ground and first-floor slabs for any signs of movement, cracking, or settlement. Ensure that the slabs are securely bolted to the PRC panels.

- Check Ceiling Joists: Examine the timber joists and steel stanchions supporting the ceilings for any signs of damage or deterioration.

Asbestos-Containing Materials

- Identify Asbestos: Have a professional survey conducted to identify any asbestos-containing materials, such as asbestos cement slates. Proper management and removal of asbestos are essential to ensure the safety of the occupants.

Structural Integrity

- Assess Reinforcement Cover: Evaluate the cover to the reinforcement in PRC panels and ground beams. Inadequate cover can lead to corrosion and compromise the structural integrity of the property.

- Check for Movement: Look for any signs of movement or settlement in the structure, particularly around the connections between trusses, walls, and floor beams.

Conclusion

The Bates 4L house is a unique and historically significant property type that offers both opportunities and challenges for home buyers and investors. Understanding the construction details, typical hazards, and potential defects is crucial for making informed decisions when purchasing a Bates 4L house.

At Flettons, we’re committed to safeguarding your investment. When considering a property purchase, trust our seasoned expertise to reveal any hidden threats. For a thorough building survey, get your instant quote through our quote calculator or reach out directly at 0203 691 0451. Your home’s safety is our top priority.