The Beanland No. 2 House: A Comprehensive Guide for Home Buyers and Investors

Historical Context and Manufacturing Background

The Beanland No. 2 house, a product of Beanland Unit Construction Ltd, is a notable example of post-war British architecture. These properties were constructed in the 1940s, a period marked by a significant housing shortage due to the aftermath of World War II. The need for rapid and cost-effective housing solutions led to the development of various system-built properties, including the Beanland No. 2 house.

Beanland Unit Construction Ltd, both the designer and manufacturer, produced a total of 102 units of this specific house type. These properties are predominantly found in suburban areas across the UK, where they were erected to accommodate the growing population and the urgent need for housing.

Architectural and Structural Characteristics

General Identification Characteristics

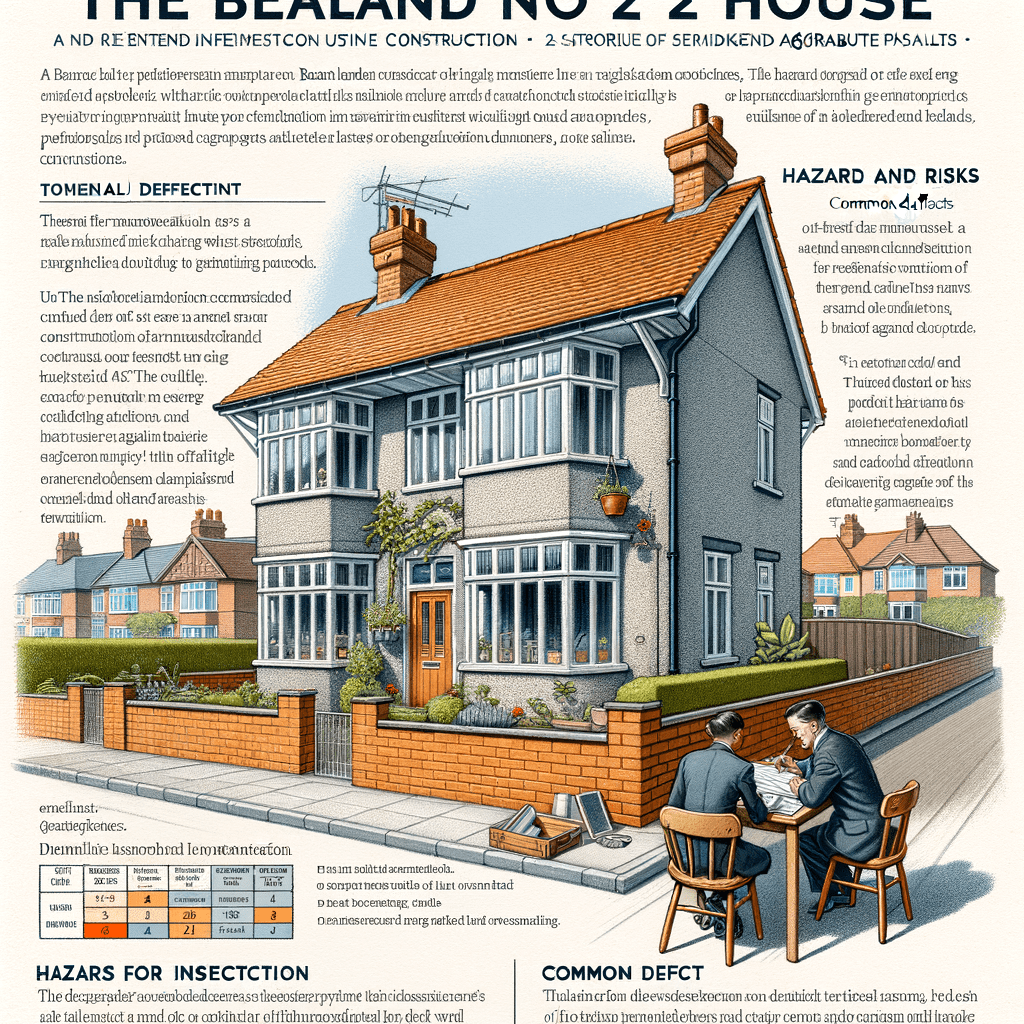

The Beanland No. 2 house is a two-storey semi-detached property, easily identifiable by its shallow pitch gable roof covered with bituminous felt. The external walls are rendered throughout, providing a uniform and somewhat austere appearance. One of the distinctive features is the exposed Precast Reinforced Concrete (PRC) beam at the first-floor level, which is a hallmark of this construction type.

Other notable features include a flat concrete canopy over the front door and PRC window surrounds, which add to the unique aesthetic of the property. These characteristics make the Beanland No. 2 house relatively easy to identify for those familiar with post-war British architecture.

Construction Details

Substructure

The substructure of the Beanland No. 2 house consists of reinforced concrete (RC) trench footings, which provide a stable foundation. An asphalt damp-proof course (DPC) is used to prevent moisture from rising through the structure, a common practice in properties of this era.

Frame

The main frame of the house is constructed using RC columns and PRC beams. This combination provides the necessary structural support while allowing for relatively quick and efficient construction.

External Walls

The external walls are rendered and consist of a layered construction. The outer layer is made of 2-inch dense aggregate precast concrete (PC) panels, followed by a 3-inch cavity, and then 2-inch sawdust PC panels. This multi-layered approach provides both insulation and structural integrity. Wire ties are used to secure the panels in place, ensuring stability.

Separating Wall

The separating wall between the semi-detached units is constructed similarly to the external walls, with RC columns and PRC beams, 2-inch dense aggregate PC panels, a 2-inch cavity, and 2-inch sawdust PC panels. This design provides sound insulation and fire resistance between the two units.

Partitions

Internal partitions are made of sawdust PC slabs, which are lightweight and provide adequate separation between rooms.

Floors

The ground floor is constructed of concrete, providing a solid and durable base. The first floor consists of timber boarding on timber joists, a common practice in houses of this period.

Ceilings

Ceilings are made of plasterboard, which is easy to install and provides a smooth finish.

Roof

The roof structure consists of steel trusses, lightweight PC slabs, 5-inch purlins, and bituminous felt. This combination provides a lightweight yet durable roof that can withstand the elements.

Variants

Some variants of the Beanland No. 2 house feature an inner leaf of external walls made of clinker aggregate PC panels instead of the standard sawdust PC panels. This variation can affect the thermal and acoustic properties of the house.

Typical Hazards and Risks

Structural Integrity

One of the primary concerns with the Beanland No. 2 house is the potential for structural issues due to the use of PRC beams and columns. Over time, these components can suffer from corrosion, particularly if the concrete cover is insufficient or if the steel reinforcement is exposed to moisture. This can lead to a loss of structural integrity and, in severe cases, structural failure.

Damp and Moisture Ingress

Despite the use of an asphalt DPC, damp and moisture ingress can still be an issue, particularly if the DPC has deteriorated over time. This can lead to problems such as mould growth, wood rot, and damage to internal finishes.

Thermal Insulation

The original construction of the Beanland No. 2 house does not provide a high level of thermal insulation. The use of dense aggregate and sawdust PC panels offers some insulation, but modern standards are much higher. This can result in higher heating costs and a less comfortable living environment.

Asbestos

As with many properties built in the mid-20th century, there is a potential risk of asbestos being present in the Beanland No. 2 house. Asbestos was commonly used in building materials for its fire-resistant properties, but it poses significant health risks if disturbed.

Defective Premises Act Considerations

The Beanland No. 2 house is not specifically listed as defective under the Defective Premises Act. However, the potential for structural issues due to the use of PRC components means that buyers and investors should exercise caution. It is advisable to have a thorough survey conducted by a qualified professional to assess the condition of the property and identify any potential defects.

Inspection and Assessment Guide

Pre-Inspection Preparation

Before conducting an inspection of a Beanland No. 2 house, it is essential to gather as much information as possible about the property. This includes reviewing any available documentation, such as previous survey reports, maintenance records, and planning permissions. Familiarising yourself with the typical characteristics and potential issues of this property type will help you conduct a more thorough and effective inspection.

External Inspection

Roof

Begin by inspecting the roof for any signs of damage or deterioration. Check the condition of the bituminous felt covering and look for any signs of water ingress or leaks. Pay particular attention to the steel trusses and lightweight PC slabs, as these can be prone to corrosion and damage.

Walls

Examine the external walls for any signs of cracking, spalling, or other damage. Check the condition of the render and look for any areas where it may be deteriorating or coming away from the underlying structure. Pay close attention to the PRC beams and columns, as these are critical structural components.

Windows and Doors

Inspect the PRC window surrounds and the flat concrete canopy over the front door for any signs of damage or deterioration. Check the condition of the windows and doors themselves, including the frames and seals.

Internal Inspection

Floors

Check the condition of the ground floor concrete and the first-floor timber boarding and joists. Look for any signs of movement, sagging, or damage. Pay particular attention to areas around the edges of the rooms, as these can be prone to damp and rot.

Walls and Partitions

Inspect the internal walls and partitions for any signs of cracking, movement, or damage. Check the condition of the plasterboard ceilings and look for any signs of water damage or staining.

Damp and Moisture

Use a moisture meter to check for any signs of damp or moisture ingress. Pay particular attention to areas around windows and doors, as well as the base of the walls where the DPC may have deteriorated.

Structural Components

PRC Beams and Columns

Conduct a thorough inspection of the PRC beams and columns, both internally and externally. Look for any signs of corrosion, cracking, or spalling. If any issues are identified, it may be necessary to conduct further investigations, such as taking core samples or using non-destructive testing methods.

Asbestos

If there is any suspicion that asbestos may be present, it is essential to have a specialist asbestos survey conducted. This will identify any asbestos-containing materials and provide guidance on how to manage or remove them safely.

Typical Defects and Maintenance Considerations

Corrosion of PRC Components

One of the most common defects in the Beanland No. 2 house is the corrosion of PRC components. This can lead to cracking, spalling, and a loss of structural integrity. Regular inspections and maintenance are essential to identify and address any issues before they become severe.

Damp and Moisture Ingress

Damp and moisture ingress can cause significant damage to the property if not addressed promptly. Regular inspections and maintenance of the DPC, as well as addressing any issues with the external render, can help prevent these problems.

Thermal Insulation Upgrades

Given the relatively low level of thermal insulation in the original construction, upgrading the insulation can significantly improve the energy efficiency and comfort of the property. This may involve adding insulation to the walls, roof, and floors, as well as upgrading windows and doors.

Asbestos Management

If asbestos is present in the property, it is essential to manage it safely. This may involve encapsulating or removing asbestos-containing materials, depending on their condition and location. Always use a qualified asbestos specialist to conduct any work involving asbestos.

Conclusion

The Beanland No. 2 house is a unique and historically significant property type that offers both opportunities and challenges for home buyers and investors. Understanding the typical characteristics, potential hazards, and maintenance considerations is essential for making an informed decision when purchasing one of these properties.

At Flettons, we’re committed to safeguarding your investment. When considering a property purchase, trust our seasoned expertise to reveal any hidden threats. For a thorough building survey, get your instant quote through our quote calculator or reach out directly at 0203 691 0451. Your home’s safety is our top priority.