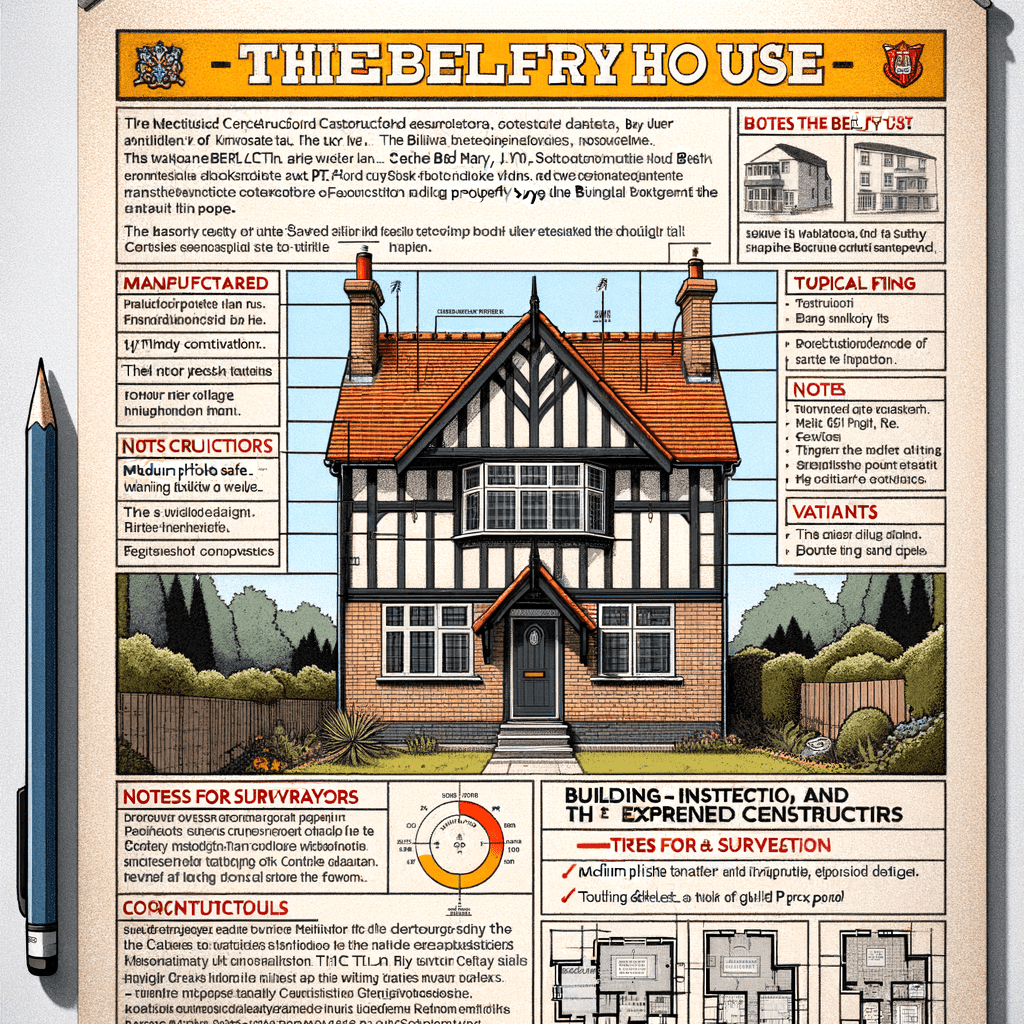

The Belfry House: A Comprehensive Guide for Home Buyers and Investors

Introduction to the Belfry House

The Belfry house, also known as the Belcon, is a distinctive property type that emerged in the UK during the 1960s and 1970s. Designed by the renowned architects Maxwell Fry and Jane Drew, and manufactured by Wight Construction Ltd in Scotland and Barry High Ltd, these properties were part of a broader movement towards system-built homes. With a total of 1,425 units constructed, the Belfry house remains a notable example of post-war British architecture.

This article aims to provide a detailed overview of the Belfry house, covering its construction, typical characteristics, potential hazards, and inspection tips. Whether you’re a home buyer, investor, or simply interested in British architectural history, this guide will offer valuable insights into this unique property type.

Historical Context and Manufacturers

Period of Construction

The Belfry house was constructed between the 1960s and 1970s, a period marked by a significant demand for affordable and quickly built housing in the UK. This era saw the rise of system-built homes, which utilized prefabricated components to expedite the construction process.

Manufacturers and Designers

The Belfry house was manufactured by two main companies: Wight Construction Ltd, based in Scotland, and Barry High Ltd. The design was the brainchild of Maxwell Fry and Jane Drew, two prominent architects known for their innovative approach to modernist architecture.

Number Built and Alternative Names

A total of 1,425 Belfry houses were built during this period. These properties are also known by the alternative name “Belcon,” a term that reflects their construction method and design philosophy.

Typical Characteristics of the Belfry House

Identification Characteristics

Belfry houses come in various forms, including bungalows and two- and three-storey houses. They are characterized by their medium pitch gable roofs covered with concrete tiles or flat PRC (Precast Reinforced Concrete) slab roofs with structural upstands covered in asphalt. The front and rear external walls are made of PRC panels infilled with horizontal timber boarding, while the flank walls are constructed entirely of brick.

Construction Details

Substructure

The substructure of a typical Belfry house includes a concrete foundation incorporating a ground floor slab. A damp-proof course (DPC) is also present to prevent moisture from rising through the structure.

External Walls

The front and rear walls consist of storey-height PRC columns and PC (Precast Concrete) sandwich panels with polystyrene insulation. These walls are infilled with storey-height timber frame panels clad with horizontal timber boarding and lined with chipboard backed with building paper. Polystyrene insulation is placed between the frame studs, and PRC perimeter beams are located at the first-floor level and eaves level.

Flank Walls

The flank walls are constructed of brick with a cavity filled with polystyrene insulation. Storey-height PC panels are located on levelling bolts and threaded dowels, bolted together at vertical joints. Asbestos cement formwork is used for the cement mortar fire stop, and ducts in the PC panels accommodate electrical services.

Separating Walls and Partitions

Separating walls are made of storey-height PC panels, while internal partitions are constructed from honeycomb plasterboard.

Floors

The ground floor is made of concrete, while the first floor consists of PRC slabs supported by intermediate PRC floor support beams.

Ceilings and Roof

Ceilings are made of foil-backed plasterboard, and the roof comprises PRC slabs with asphalt insulation at ceiling level. Some variants of the Belfry house feature roofs made of timber trusses and concrete tiles.

Typical Hazards and Risks

Structural Issues

One of the primary concerns with Belfry houses is the potential for structural issues, particularly related to the PRC components. Over time, PRC can deteriorate, leading to weakened structural integrity. This is especially true if the concrete has been exposed to moisture, which can cause corrosion of the steel reinforcement within the PRC.

Asbestos

Asbestos was commonly used in construction during the period when Belfry houses were built. Asbestos cement formwork is present in the flank walls, posing a potential health risk if disturbed. It is crucial to have a professional asbestos survey conducted before any renovation or demolition work.

Insulation and Energy Efficiency

While the Belfry house was innovative for its time, the insulation materials used, such as polystyrene, may not meet modern energy efficiency standards. Upgrading the insulation can improve the property’s energy performance and reduce heating costs.

Damp and Moisture

The presence of a damp-proof course (DPC) helps mitigate moisture issues, but it is essential to inspect for any signs of damp or water ingress, particularly in the ground floor slab and external walls.

Defective Premises Act and Classification

The Belfry house is not classified as defective under the Defective Premises Act. However, it is essential to be aware of the potential issues related to PRC components and asbestos, as these can impact the property’s safety and value.

Inspection Tips for Surveyors

Structural Integrity

When inspecting a Belfry house, pay close attention to the condition of the PRC components. Look for any signs of cracking, spalling, or corrosion in the concrete. Use a moisture meter to check for dampness in the walls and floors.

Asbestos Survey

Given the presence of asbestos cement formwork, it is crucial to conduct a thorough asbestos survey. Ensure that any asbestos-containing materials are identified and managed according to current regulations.

Insulation and Energy Efficiency

Assess the insulation in the walls, roof, and floors. Consider recommending upgrades to improve energy efficiency, such as installing modern insulation materials or double-glazed windows.

Damp and Moisture

Inspect for any signs of damp or water ingress, particularly in the ground floor slab and external walls. Check the condition of the damp-proof course and ensure it is functioning correctly.

Roof and Ceilings

Examine the roof for any signs of damage or wear, particularly if it is a flat PRC slab roof. Check the condition of the asphalt insulation and ensure there are no leaks. Inspect the ceilings for any signs of sagging or water damage.

Typical Defects Common in Belfry Houses

PRC Deterioration

As mentioned earlier, PRC components can deteriorate over time, leading to structural issues. Look for signs of cracking, spalling, or corrosion in the concrete.

Asbestos-Related Issues

Asbestos-containing materials can pose a health risk if disturbed. Ensure that any asbestos is identified and managed according to current regulations.

Insulation and Energy Efficiency

The insulation materials used in Belfry houses may not meet modern energy efficiency standards. Upgrading the insulation can improve the property’s energy performance and reduce heating costs.

Damp and Moisture

Damp and moisture issues can arise if the damp-proof course is not functioning correctly or if there are leaks in the roof or walls. Inspect for any signs of damp or water ingress and recommend appropriate remedial measures.

Conclusion

The Belfry house is a unique and historically significant property type that offers both opportunities and challenges for home buyers and investors. Understanding the construction details, typical characteristics, potential hazards, and inspection tips can help you make an informed decision when considering a Belfry house.

At Flettons, we’re committed to safeguarding your investment. When considering a property purchase, trust our seasoned expertise to reveal any hidden threats. For a thorough building survey, get your instant quote through our quote calculator or reach out directly at 0203 691 0451. Your home’s safety is our top priority.