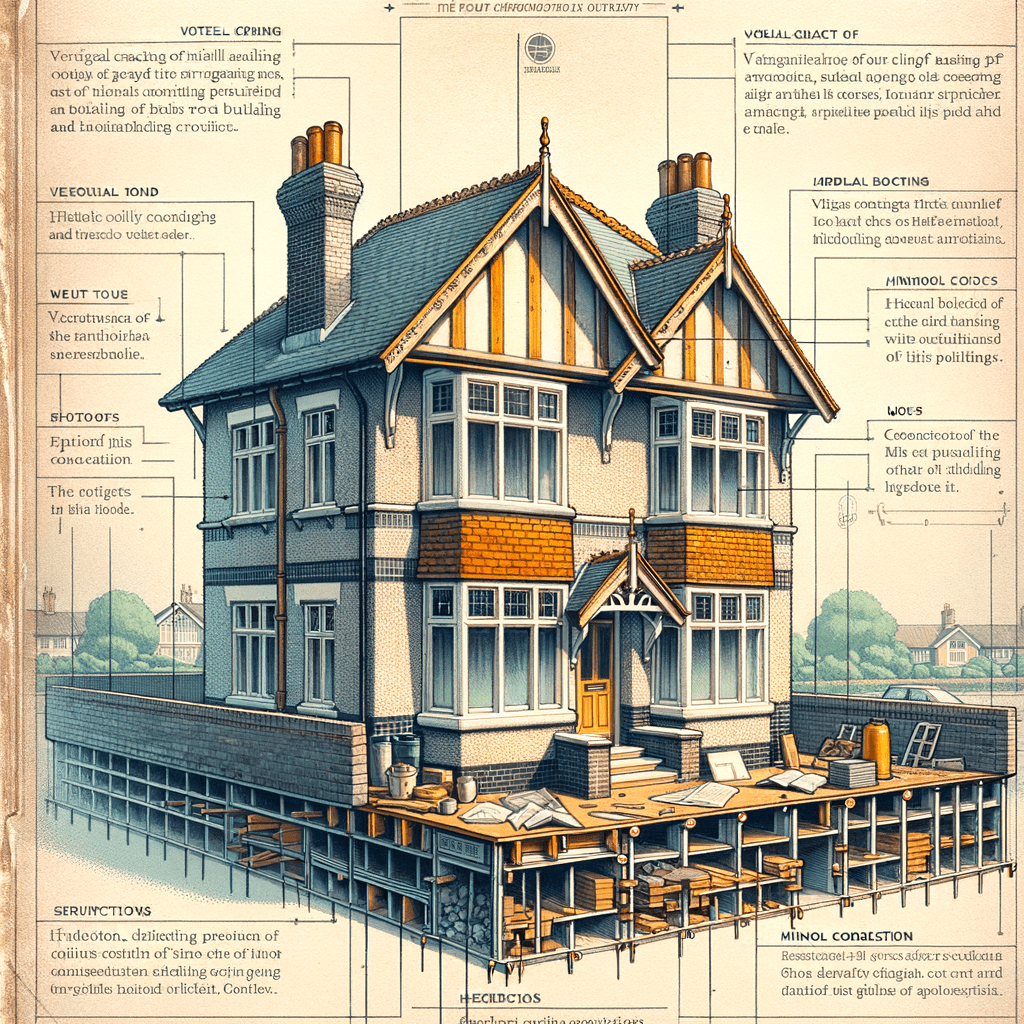

The Boot Pier and Panel House: A Comprehensive Guide for Home Buyers and Investors

Historical Context and Manufacturing Background

The Boot Pier and Panel house, often referred to simply as the “Boot house,” is a significant part of the UK’s architectural history. These properties were primarily constructed between 1910 and 1930 by Henry Boot & Sons Ltd, a prominent construction company of the time. The Boot house is a type of system-built property, which means it was constructed using pre-fabricated components, a method that was innovative and efficient for its era.

Henry Boot & Sons Ltd, the manufacturer, was a key player in the construction industry during the early 20th century. The company was known for its pioneering techniques in pre-fabrication, which allowed for rapid construction and cost savings. The Boot house is a testament to their ingenuity, designed to address the housing shortages of the time by providing affordable and quickly assembled homes.

Typical Locations and Distribution

Approximately 8,200 Boot houses were built across the UK, with a significant concentration in urban and suburban areas. These properties were often found in regions experiencing rapid industrial growth, where the demand for worker housing was high. Cities like Sheffield, Manchester, and Birmingham saw a substantial number of these homes, although they can be found in various other parts of the country as well.

Architectural Characteristics

External Features

Boot houses are typically two-storey semi-detached or terraced properties. One of the most distinctive features is their shallow or medium pitch hipped roofs, which are usually covered with tiles. The external walls are rendered throughout, giving the houses a uniform and somewhat austere appearance. Some of these houses also feature ground floor flat-roofed bay windows, adding a touch of architectural variety.

Internal Features

Internally, Boot houses were designed with practicality in mind. The ground floor typically consists of timber boarding on timber joists, while the first floor follows a similar construction method. Partitions within the house are made of timber stud lined with plasterboard, providing a straightforward and functional layout.

Construction Details

Substructure

The substructure of Boot houses consists of concrete strip footings and concrete under-building. This foundation method was standard for the time and provided a stable base for the pre-fabricated components.

Frame

The main frame of the house is constructed using double 3″ storey height pre-cast reinforced concrete (PRC) columns, separated by a 2″ cavity and tied together with mild steel (MS) ties. At the first-floor level, double PRC ring beams are used, while reinforced concrete (RC) ring beams are found at the eaves level. A timber wall plate is also incorporated into the design.

External Walls

The external walls are made of rendered clinker aggregate concrete slab cavity walls, measuring 2’8″ x 9″ x 3″. These walls include a 2″ cavity, which was intended to provide some degree of insulation and moisture control.

Separating Walls and Partitions

Separating walls between properties are also constructed using clinker aggregate slab cavity walls. Internal partitions are made of timber stud lined with plasterboard, which was a common and cost-effective method at the time.

Floors and Ceilings

Both the ground and first floors are constructed using timber boarding on timber joists. The specific details of the ceilings are not well-documented, but they are likely to be similar to other properties of the era, possibly using plasterboard or lath and plaster.

Roof

The roof construction details are not extensively documented, but it is known that the roofs are typically hipped and covered with tiles. The exact materials and methods used for the roof structure may vary between properties.

Common Defects and Hazards

Vertical Cracking of PRC Columns

One of the most common defects in Boot houses is the vertical cracking of the clinker aggregate PRC columns. This issue arises due to the inherent brittleness of the clinker aggregate concrete and the stresses placed on the columns over time.

Cracking of Render

The external render on Boot houses is also prone to cracking. This can be caused by a variety of factors, including thermal expansion and contraction, moisture ingress, and the natural aging of the materials.

Corrosion of Wall Ties

The mild steel ties used to connect the PRC columns are susceptible to corrosion, especially in damp conditions. This corrosion can weaken the structural integrity of the house and lead to further issues.

Minor Corrosion of Column Tie Rods

In addition to the wall ties, the column tie rods can also experience minor corrosion. While this is generally less severe than the corrosion of the wall ties, it can still contribute to the overall degradation of the structure.

Defective Premises Act and Designation

Boot houses are designated as defective under the Defective Premises Act. This designation means that these properties are recognized as having inherent structural issues that can affect their safety and habitability. As a result, buyers and investors should approach these properties with caution and ensure that thorough inspections are carried out before making any purchase decisions.

Inspection Guide for Surveyors

When inspecting a Boot house, surveyors should pay close attention to the following areas:

External Walls and Render

Check for any signs of cracking or damage to the external render. Look for vertical cracks in the PRC columns, as these can indicate significant structural issues.

Wall Ties and Column Tie Rods

Inspect the wall ties and column tie rods for any signs of corrosion. This may involve removing small sections of render to gain access to the ties.

Roof Structure

Examine the roof structure for any signs of damage or deterioration. Pay particular attention to the condition of the tiles and the integrity of the hipped roof design.

Internal Partitions and Floors

Check the internal partitions and floors for any signs of movement or instability. Look for cracks in the plasterboard and any signs of sagging or unevenness in the floors.

Substructure and Foundations

Inspect the substructure and foundations for any signs of settlement or movement. This may involve checking for cracks in the concrete strip footings and under-building.

Variants and Modifications

Over the years, some Boot houses have undergone modifications and repairs. These can include:

Eaves Height PRC Columns

Some properties may have PRC columns that extend to the eaves height, providing additional structural support.

First Floor Separating Wall of Brick

In some cases, the first-floor separating wall may be constructed of brick rather than clinker aggregate slab. This can provide additional strength and stability.

PRC Dense Aggregate Columns and Beams

Some Boot houses may feature PRC dense aggregate columns and beams, which can offer improved durability compared to the original clinker aggregate components.

Metal Ties and Anchor Plates

In certain properties, metal ties between corner and adjacent columns may be absent. Instead, metal ties passing from the front to the back of the house and fixed into external anchor plates may be used.

Conclusion

The Boot Pier and Panel house is a fascinating example of early 20th-century system-built housing in the UK. While these properties were innovative for their time, they do come with a range of potential defects and hazards that buyers and investors need to be aware of. By understanding the construction methods, common issues, and inspection requirements, you can make informed decisions when considering a Boot house.

At Flettons, we’re committed to safeguarding your investment. When considering a property purchase, trust our seasoned expertise to reveal any hidden threats. For a thorough building survey, get your instant quote through our quote calculator or reach out directly at 0203 691 0451. Your home’s safety is our top priority.