The Carlton House: A Comprehensive Guide for Home Buyers and Investors

Historical Context and Background

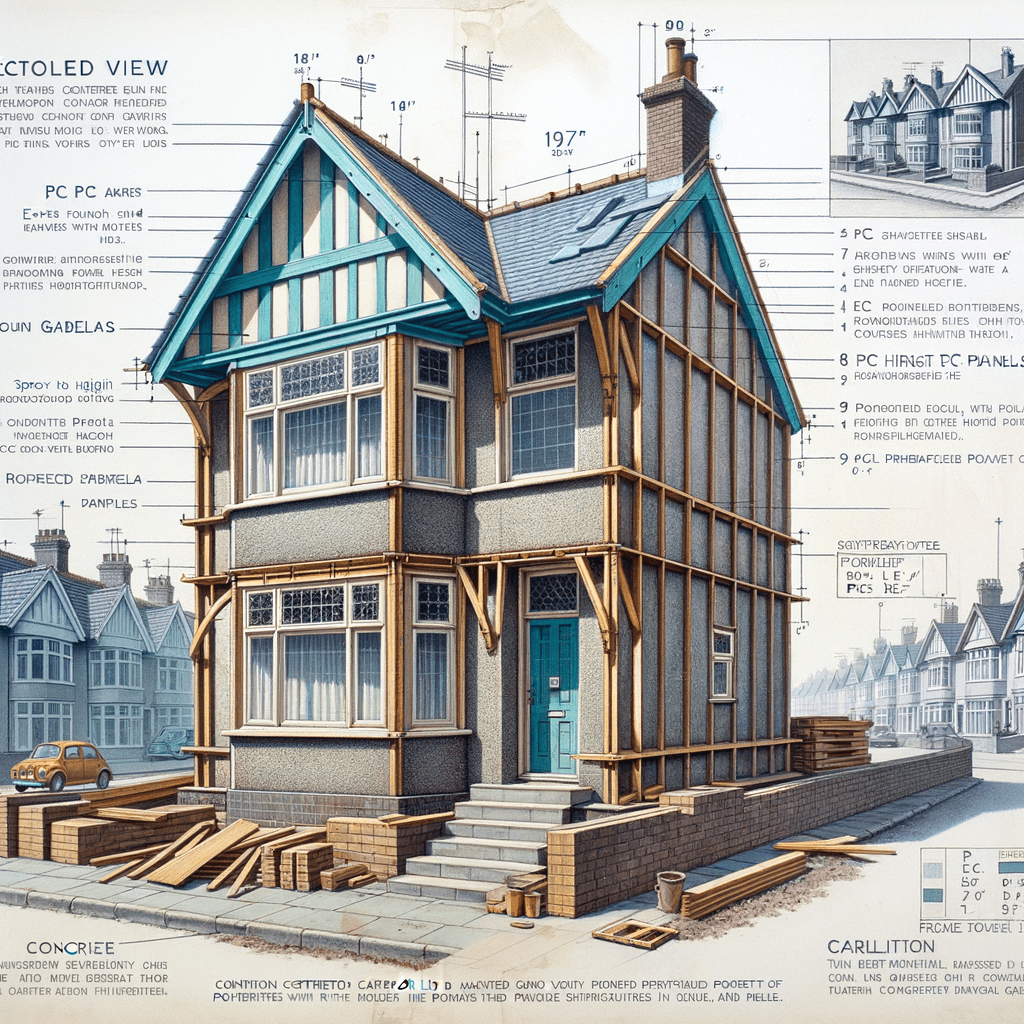

The Carlton House, a notable example of system-built properties in the UK, emerged during a period of rapid post-war reconstruction. Built between 1965 and the late 1960s, these properties were designed by R Pianca and constructed by Carlton Contractors Ltd. The primary manufacturer of the materials used in these homes was Concrete Ltd. Approximately 350 Carlton Houses were built, primarily as 2-storey terraced houses, although the system was also adapted for flats.

The Carlton House was part of a broader movement to address the housing shortage in the UK during the mid-20th century. The use of prefabricated reinforced concrete (PRC) allowed for quicker construction times and reduced costs, making it an attractive option for local authorities and developers.

Design and Construction Characteristics

External Features

Carlton Houses are easily identifiable by their shallow pitch gable roofs covered with concrete tiles. The front and rear external walls are constructed with eaves-height PRC columns infilled with vertical timber boarding. At the first-floor level, a spandrel PC panel is typically present, while the gable walls consist of storey-height PC panels. Aluminium fascias are another distinctive feature of these properties.

Internal Structure

Substructure

The substructure of Carlton Houses includes pad foundations with locating dowels set in concrete, PRC ground beams, and a concrete slab. This robust foundation system was designed to provide stability and support for the prefabricated components.

External Walls

The front and rear walls are constructed with eaves-height PC columns infilled with timber frame panels clad with vertical timber boarding. A 6″ x 4′ fluted PRC spandrel panel is bolted to cleats, providing additional structural integrity.

Gable Walls

The gable walls are made of 8″ storey-height PC cavity wall panels, with a PC apex panel at the top. This design ensures that the gable ends are both strong and weather-resistant.

Separating Walls

The separating walls between properties are constructed from 7″ concrete, providing sound insulation and fire resistance.

Partitions

The internal partitions within Carlton Houses are not well-documented, but they are likely to be constructed from lightweight materials to facilitate quick assembly.

Floors

The ground floor is typically a concrete slab, while the first floor consists of 9 1/2″ voided PC panels. These panels provide a solid and stable base for the upper storey.

Ceilings

The ceilings are generally made of plasterboard, which is a common material used in many types of housing for its ease of installation and finish.

Roof

The roof structure includes timber trusses, PC purlins, and concrete tiles. The use of timber trusses provides flexibility in the roof design, while the concrete tiles offer durability and weather resistance. Aluminium fascias are used to finish the roof edges, providing a clean and modern appearance.

Typical Hazards and Risks

Vertical Cracking of PC Columns

One of the most common issues with Carlton Houses is vertical cracking in the PRC columns. This can be caused by a variety of factors, including thermal expansion and contraction, settlement of the foundations, and general wear and tear over time.

Cracking and Spalling of Gable and Spandrel PC Panels

Cracking and spalling (the breaking off of pieces) of the gable and spandrel PC panels are also common issues. This can be due to the carbonation of the concrete, which reduces its strength and durability. Low concrete cover to the reinforcement in PRC columns can exacerbate this problem, as it leaves the steel reinforcement more exposed to the elements.

Carbonation of PC Panels

Carbonation is a chemical reaction that occurs when carbon dioxide from the air penetrates the concrete and reacts with the calcium hydroxide in the cement. This process reduces the alkalinity of the concrete, which can lead to the corrosion of the steel reinforcement. Over time, this can weaken the structural integrity of the panels.

Low Concrete Cover to Reinforcement

In some cases, the concrete cover to the reinforcement in PRC columns is insufficient. This can leave the steel reinforcement more vulnerable to corrosion, particularly in areas with high levels of moisture or pollution.

Defective Premises Act and Carlton Houses

The Defective Premises Act 1972 imposes a duty on builders, developers, and landlords to ensure that properties are constructed and maintained to a reasonable standard. Carlton Houses, like many other system-built properties from this era, have been subject to scrutiny under this legislation.

While not all Carlton Houses are automatically classed as defective, the issues outlined above can lead to significant problems if not addressed. It is essential for potential buyers and investors to be aware of these risks and to seek professional advice before purchasing a Carlton House.

Inspection Guide for Surveyors

When inspecting a Carlton House, surveyors should pay close attention to the following areas:

External Walls

- Check for vertical cracking in PRC columns: Look for any signs of cracking, particularly around the base and top of the columns.

- Inspect timber boarding: Ensure that the timber boarding is in good condition and free from rot or insect damage.

- Examine spandrel panels: Look for any signs of cracking or spalling, particularly around the edges and corners.

Gable Walls

- Check for cracking and spalling: Inspect the gable walls for any signs of damage, particularly around the joints and edges.

- Assess the condition of the PC panels: Look for any signs of carbonation or other chemical damage.

Roof

- Inspect the roof structure: Check the condition of the timber trusses, PC purlins, and concrete tiles. Look for any signs of damage or wear, particularly around the edges and joints.

- Examine the aluminium fascias: Ensure that the fascias are securely attached and free from corrosion or other damage.

Internal Structure

- Check the condition of the concrete floors: Look for any signs of cracking or settlement, particularly around the edges and corners.

- Inspect the plasterboard ceilings: Ensure that the ceilings are in good condition and free from cracks or other damage.

General Condition

- Assess the overall condition of the property: Look for any signs of general wear and tear, including peeling paint, damp patches, or other signs of neglect.

- Check for any signs of structural movement: Look for any signs of settlement or movement, particularly around the foundations and load-bearing walls.

Typical Defects and Maintenance Tips

Vertical Cracking of PC Columns

To address vertical cracking in PRC columns, it is essential to identify the underlying cause. This may involve a detailed structural assessment by a qualified engineer. In some cases, it may be necessary to reinforce or replace the affected columns to ensure the structural integrity of the property.

Cracking and Spalling of Gable and Spandrel PC Panels

Cracking and spalling of gable and spandrel PC panels can be addressed through a combination of repair and maintenance. This may involve patching or replacing damaged panels, as well as applying protective coatings to prevent further damage. Regular inspections and maintenance are essential to identify and address any issues before they become more serious.

Carbonation of PC Panels

To address carbonation of PC panels, it is essential to identify the extent of the damage and take appropriate action. This may involve applying protective coatings to the affected areas, as well as reinforcing or replacing damaged panels. Regular inspections and maintenance are essential to identify and address any issues before they become more serious.

Low Concrete Cover to Reinforcement

To address low concrete cover to reinforcement, it may be necessary to apply additional protective coatings or reinforcement to the affected areas. This can help to prevent further corrosion and ensure the structural integrity of the property. Regular inspections and maintenance are essential to identify and address any issues before they become more serious.

Conclusion

The Carlton House represents a significant chapter in the history of UK housing, reflecting the innovative approaches to construction that emerged in the mid-20th century. While these properties offer unique architectural features and historical value, they also come with specific challenges and risks that potential buyers and investors must consider.

Understanding the typical construction methods, common defects, and maintenance requirements of Carlton Houses is essential for making informed decisions. By conducting thorough inspections and seeking professional advice, buyers can ensure that they are fully aware of the condition of the property and any potential issues that may arise.

At Flettons, we’re committed to safeguarding your investment. When considering a property purchase, trust our seasoned expertise to reveal any hidden threats. For a thorough building survey, get your instant quote through our quote calculator or reach out directly at 0203 691 0451. Your home’s safety is our top priority.