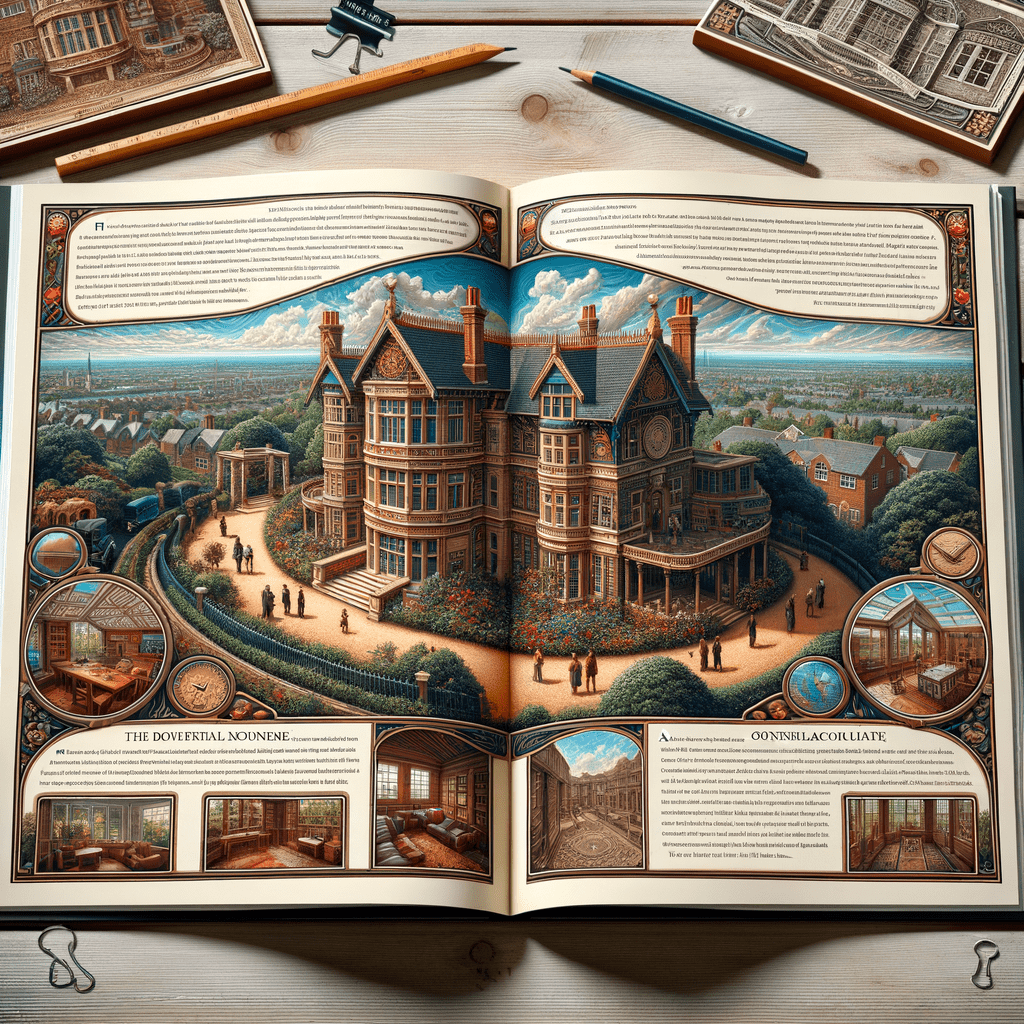

The Thames House: A Comprehensive Guide for Home Buyers and Investors

Understanding the Thames House

The Thames House, a distinctive property type, emerged in the 1940s as a response to the housing demands of post-war Britain. Designed by Joseph Emberton and manufactured by Briggs Motor Bodies Ltd, these homes are a testament to the innovative spirit of the era. Known for their unique construction and design, Thames Houses are primarily found in various parts of the UK, offering a glimpse into the architectural trends of the mid-20th century.

Historical Context and Manufacturing

The 1940s was a period marked by a significant housing shortage in the UK, largely due to the destruction caused by World War II. In response, the government and private manufacturers sought to develop quick and efficient housing solutions. The Thames House was one such solution, designed to be both economical and durable. Briggs Motor Bodies Ltd, a company with a strong background in manufacturing, took on the challenge of producing these homes. Their expertise in metalwork and assembly line production made them an ideal candidate for this task.

Design and Construction Characteristics

Thames Houses are easily identifiable by their two-storey, semi-detached structure. One of the most striking features is the curved ribbed roof, covered with bituminous felt, which gives the house a distinctive silhouette. The external walls are made entirely of steel sheets, a choice that reflects the industrial capabilities of the time.

The construction of Thames Houses involves several key components:

-

Substructure: These homes are built on concrete strip footings with a concrete under-building, providing a solid foundation. A damp-proof course (DPC) is included to prevent moisture ingress.

-

Frame: The frame consists of PS ring beams at both ground and first-floor levels, with storey-height PSC frame panels. Double PSC floor joists form an I-section at both levels, ensuring structural integrity.

-

Protective Coating: To protect against corrosion, the panels are stoved with a coat of red oxide-alkyd primer and an undercoat. Perimeter beams are sprayed with zinc and coated with aluminised bituminous paint.

-

External Walls: The walls are constructed from steel sheets, aerated concrete, and plaster, providing both strength and insulation.

-

Separating Wall: A cavity wall of PSC panels infilled with aerated concrete, backed with steel sheets, and lined with plaster ensures sound and thermal insulation between adjoining properties.

-

Partitions: Internal partitions are made from steel framing infilled with aerated concrete, maintaining the structural theme throughout the house.

-

Floors: The ground and first floors feature timber boarding on steel joists, offering a balance of flexibility and strength.

-

Ceilings: PS trays are used for ceilings, with the ground floor infilled with aerated concrete for additional insulation.

-

Roof: The roof is constructed from curved steel panels, with edges turned up and sealed with a capping piece, then covered with bituminous felt for weatherproofing.

Typical Hazards and Risks

While Thames Houses are robust, they are not without their challenges. The use of steel in construction, while innovative, can lead to specific issues over time. Corrosion is a primary concern, particularly if the protective coatings have deteriorated. Moisture ingress can exacerbate this problem, leading to structural weaknesses.

Another potential risk is the thermal performance of the property. Steel, being a conductor, can lead to heat loss, making these homes less energy-efficient compared to modern standards. Retrofitting with additional insulation can mitigate this issue but requires careful planning to avoid compromising the structure.

Defective Premises Act Considerations

Under the Defective Premises Act, properties must be fit for habitation. Thames Houses, due to their age and construction materials, may require assessment to ensure compliance. While not inherently classified as defective, the potential for corrosion and thermal inefficiency means that buyers should conduct thorough inspections before purchase.

Inspection and Assessment Guide

For those considering purchasing a Thames House, a detailed inspection is crucial. Here’s a step-by-step guide to assessing these properties:

-

Exterior Inspection: Begin by examining the external steel sheets for signs of rust or corrosion. Pay particular attention to joints and seams where moisture may have penetrated.

-

Roof Assessment: Inspect the bituminous felt covering for wear and tear. Look for any signs of water ingress, such as staining or damp patches on the ceilings.

-

Structural Integrity: Check the PS ring beams and PSC frame panels for any signs of movement or damage. Ensure that the protective coatings are intact to prevent corrosion.

-

Thermal Performance: Evaluate the insulation levels in walls, floors, and ceilings. Consider the potential need for retrofitting to improve energy efficiency.

-

Moisture Control: Verify the effectiveness of the damp-proof course and look for any signs of rising damp or condensation within the property.

-

Interior Condition: Inspect the timber flooring and steel joists for any signs of rot or weakness. Ensure that internal partitions are sound and free from damage.

-

Compliance Check: Ensure that the property meets current building regulations and standards, particularly concerning safety and energy efficiency.

Common Defects and Maintenance Tips

Thames Houses, like any property, can develop defects over time. Here are some common issues and maintenance tips:

-

Corrosion: Regularly inspect and maintain the protective coatings on steel components. Reapply coatings as necessary to prevent rust.

-

Thermal Bridging: Consider installing additional insulation to reduce heat loss and improve energy efficiency. This can be achieved through cavity wall insulation or internal wall linings.

-

Moisture Management: Ensure that gutters and downpipes are clear and functioning correctly to prevent water ingress. Address any signs of damp promptly to avoid structural damage.

-

Roof Maintenance: Regularly check the condition of the bituminous felt and repair any damage to prevent leaks.

-

Structural Repairs: If any structural issues are identified, consult a professional surveyor to assess and address the problem.

Conclusion

The Thames House represents a unique chapter in the history of British housing. With their distinctive design and construction, these homes offer both charm and challenges to potential buyers. By understanding the specific characteristics and potential issues associated with Thames Houses, buyers can make informed decisions and ensure that their investment is both sound and sustainable.

At Flettons, we’re committed to safeguarding your investment. When considering a property purchase, trust our seasoned expertise to reveal any hidden threats. For a thorough building survey, get your instant quote through our quote calculator or reach out directly at 0203 691 0451. Your home’s safety is our top priority.