Cold Applied Liquid Roof Coverings: A Comprehensive Guide for UK Property Buyers and Investors

Understanding Cold Applied Liquid Roof Coverings

Cold applied liquid roof coverings have become increasingly popular in the UK due to their versatility, ease of application, and long-lasting performance. These roofing systems are particularly favoured for their ability to provide seamless, waterproof protection to a variety of roof types, including flat, pitched, and complex roof structures. In this article, we will delve into the life expectancy, performance characteristics, hazards, and risks associated with cold applied liquid roof coverings, providing you with a comprehensive understanding to make informed decisions for your property investments.

Life Expectancy of Cold Applied Liquid Roof Coverings

One of the primary considerations when choosing a roofing system is its longevity. Cold applied liquid roof coverings are known for their impressive life expectancy, which can range from 20 to 30 years, depending on the quality of the product and the expertise of the application. Here are some factors that influence the lifespan of these roofing systems:

Quality of Materials

The durability of cold applied liquid roof coverings largely depends on the quality of the materials used. High-quality products, often made from advanced polymers and resins, offer superior resistance to weathering, UV radiation, and mechanical stress. Investing in premium materials can significantly extend the life of your roof covering.

Application Process

The application process plays a crucial role in determining the longevity of cold applied liquid roof coverings. Proper surface preparation, including cleaning and priming, ensures optimal adhesion and performance. Additionally, the application should be carried out by skilled professionals who follow manufacturer guidelines to achieve a uniform and seamless finish.

Maintenance

Regular maintenance is essential to prolong the life of any roofing system. Periodic inspections, cleaning, and minor repairs can prevent small issues from escalating into major problems. Cold applied liquid roof coverings are relatively low-maintenance, but addressing any signs of wear and tear promptly can enhance their longevity.

Performance Characteristics of Cold Applied Liquid Roof Coverings

Cold applied liquid roof coverings offer a range of performance characteristics that make them an attractive choice for property owners and investors. Here are some key attributes:

Seamless Waterproofing

One of the standout features of cold applied liquid roof coverings is their ability to create a seamless, monolithic membrane. This eliminates the risk of water ingress through joints or seams, providing superior waterproofing performance. The liquid application allows the material to conform to the contours of the roof, ensuring complete coverage and protection.

Flexibility and Elasticity

Cold applied liquid roof coverings are highly flexible and elastic, allowing them to accommodate structural movements and thermal expansion without cracking or splitting. This flexibility is particularly beneficial for roofs that experience significant temperature fluctuations or dynamic loads.

UV Resistance

Exposure to UV radiation can degrade many roofing materials over time. However, cold applied liquid roof coverings are formulated with UV-resistant properties, ensuring long-term performance and protection against the harmful effects of sunlight. This makes them suitable for both residential and commercial properties.

Chemical Resistance

These roofing systems exhibit excellent resistance to a wide range of chemicals, including acids, alkalis, and industrial pollutants. This chemical resistance makes cold applied liquid roof coverings ideal for properties located in industrial areas or regions with high levels of air pollution.

Energy Efficiency

Some cold applied liquid roof coverings are designed with reflective properties that help reduce heat absorption, contributing to improved energy efficiency. By reflecting a significant portion of solar radiation, these coatings can help lower cooling costs and enhance indoor comfort.

Hazards and Risks Associated with Cold Applied Liquid Roof Coverings

While cold applied liquid roof coverings offer numerous benefits, it is important to be aware of potential hazards and risks to ensure safe and effective application. Here are some considerations:

Health and Safety Concerns

The application of cold applied liquid roof coverings involves the use of chemicals that can pose health and safety risks if not handled properly. It is essential to follow safety guidelines, including wearing appropriate personal protective equipment (PPE) such as gloves, goggles, and respirators. Adequate ventilation should be ensured to minimise exposure to fumes.

Fire Hazards

Although cold applied liquid roof coverings are generally considered safer than hot-applied systems, there is still a risk of fire if flammable materials are used or if the application process generates sparks. It is crucial to follow fire safety protocols and use non-flammable products whenever possible.

Environmental Impact

The environmental impact of cold applied liquid roof coverings depends on the specific products used. Some formulations may contain volatile organic compounds (VOCs) that can contribute to air pollution. Opting for low-VOC or VOC-free products can help minimise the environmental footprint of your roofing project.

Application Challenges

Achieving a uniform and seamless finish with cold applied liquid roof coverings requires skill and precision. Inadequate surface preparation, improper mixing, or uneven application can compromise the performance and longevity of the roofing system. Hiring experienced professionals with a proven track record can mitigate these risks.

Weather Conditions

The success of cold applied liquid roof coverings is influenced by weather conditions during application. Extreme temperatures, high humidity, or rain can affect the curing process and adhesion of the material. It is advisable to schedule the application during favourable weather conditions to ensure optimal results.

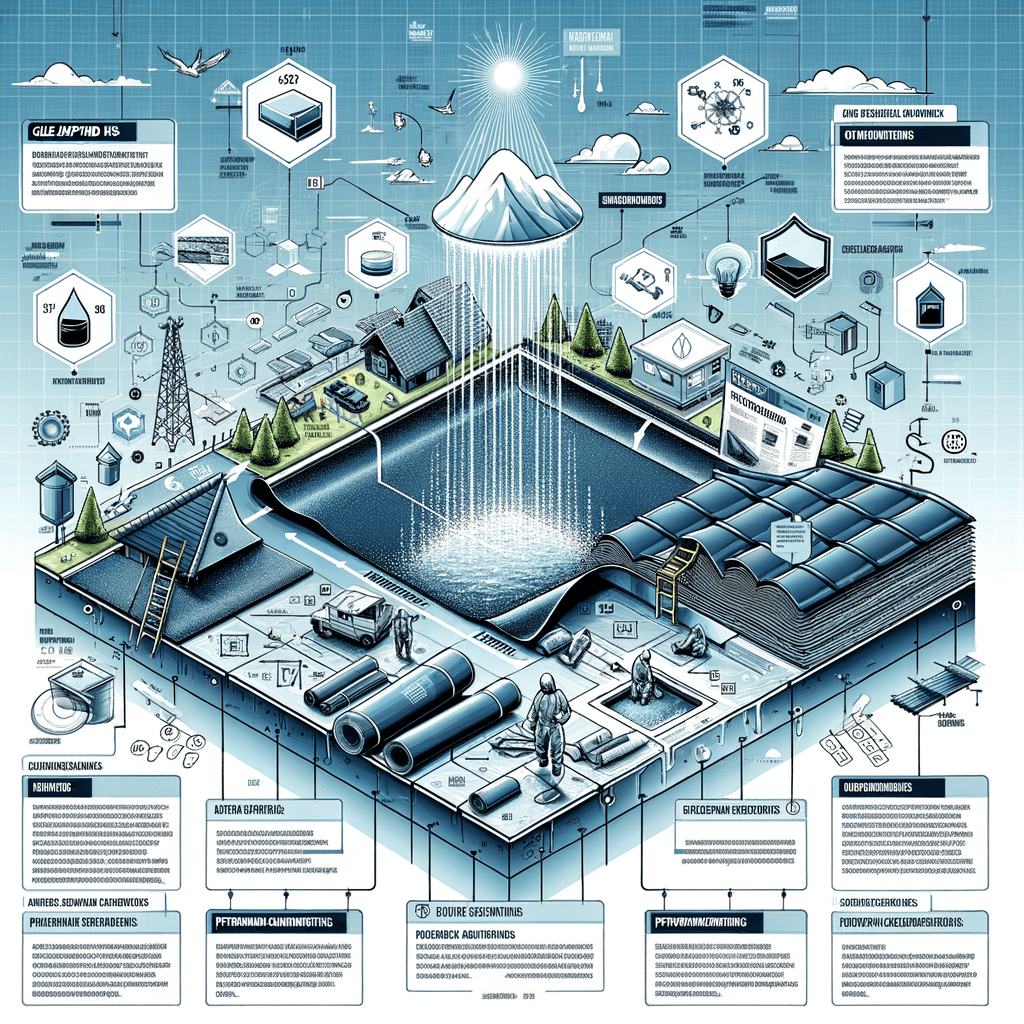

Step-by-Step Guide to Applying Cold Applied Liquid Roof Coverings

To help you understand the application process, here is a step-by-step guide to applying cold applied liquid roof coverings:

Step 1: Surface Preparation

Proper surface preparation is critical for the success of cold applied liquid roof coverings. Begin by cleaning the roof surface to remove dirt, debris, and any existing coatings. Use a pressure washer or a stiff brush to ensure a clean and smooth substrate. Repair any damaged areas, such as cracks or blisters, to create a uniform surface.

Step 2: Priming

Priming the roof surface enhances adhesion and ensures a strong bond between the substrate and the liquid coating. Apply a suitable primer according to the manufacturer’s instructions, using a roller or brush. Allow the primer to dry completely before proceeding to the next step.

Step 3: Mixing the Liquid Coating

Thoroughly mix the cold applied liquid coating to ensure a consistent and homogeneous product. Follow the manufacturer’s guidelines for mixing ratios and techniques. Use a mechanical mixer if necessary to achieve a uniform blend.

Step 4: Application

Apply the liquid coating using a roller, brush, or spray equipment, depending on the size and complexity of the roof. Start from one end and work systematically to cover the entire surface. Pay special attention to seams, joints, and penetrations to ensure complete coverage. Apply multiple coats if required, allowing each coat to dry before applying the next.

Step 5: Curing

Allow the liquid coating to cure according to the manufacturer’s recommendations. Curing times may vary depending on the product and weather conditions. Avoid foot traffic or any other activities that could disturb the coating during the curing process.

Step 6: Inspection and Maintenance

Once the coating has fully cured, conduct a thorough inspection to ensure a seamless and uniform finish. Address any imperfections or areas that require touch-ups. Regular maintenance, including periodic inspections and cleaning, will help extend the life of the cold applied liquid roof covering.

Choosing the Right Cold Applied Liquid Roof Covering

Selecting the appropriate cold applied liquid roof covering for your property involves considering several factors. Here are some key considerations to help you make an informed decision:

Roof Type and Condition

Assess the type and condition of your roof to determine the suitability of cold applied liquid roof coverings. These systems are versatile and can be applied to various roof types, including flat, pitched, and complex structures. However, the condition of the roof substrate should be evaluated to ensure proper adhesion and performance.

Climate and Weather Conditions

Consider the climate and weather conditions in your region when choosing a cold applied liquid roof covering. Some products are specifically formulated to withstand extreme temperatures, heavy rainfall, or high UV exposure. Select a coating that is designed to perform well in your local climate.

Manufacturer Reputation

Research the reputation and track record of the manufacturer before purchasing a cold applied liquid roof covering. Look for established brands with a history of producing high-quality and reliable products. Reading customer reviews and seeking recommendations from industry professionals can provide valuable insights.

Warranty and Support

Check the warranty and support offered by the manufacturer. A comprehensive warranty can provide peace of mind and protect your investment. Additionally, ensure that the manufacturer offers technical support and guidance throughout the application process.

Cost and Budget

Consider your budget when selecting a cold applied liquid roof covering. While premium products may come with a higher upfront cost, they often offer better performance and longevity. Balancing cost with quality is essential to achieve the best value for your investment.

Conclusion

Cold applied liquid roof coverings offer a versatile and durable solution for protecting your property from the elements. With their seamless waterproofing, flexibility, UV resistance, and chemical resistance, these roofing systems are well-suited for a variety of applications. However, it is important to be aware of potential hazards and risks, and to follow proper application procedures to ensure optimal performance and longevity.

At Flettons, we’re committed to safeguarding your investment. When considering a property purchase, trust our seasoned expertise to reveal any hidden threats. For a thorough building survey, get your instant quote through our quote calculator or reach out directly at 0203 691 0451. Your home’s safety is our top priority.