The Alcrete House: A Comprehensive Guide for Home Buyers and Investors

Historical Context and Manufacturing Background

The Alcrete house, a notable example of post-war British architecture, emerged in the 1940s as a response to the urgent need for housing following World War II. These properties were primarily manufactured by The Structural and Mechanical Development Engineers Ltd, with design input from the Bristol Aeroplane (Housing) Co. The Alcrete house is also known by alternative names such as Alcrete Mk I, Alcrete Mk II, and Bristol Aeroplane.

The Alcrete house was part of a broader movement towards system-built properties, which aimed to address the housing shortage quickly and efficiently. These homes were constructed using pre-fabricated components, allowing for rapid assembly on-site. The number of Alcrete houses built during this period is not precisely documented, but they were a significant part of the post-war housing landscape in the UK.

Typical Locations

Alcrete houses are predominantly found in areas that experienced significant bomb damage during World War II, necessitating rapid reconstruction. These areas include parts of London, the Midlands, and various industrial towns across the UK. The strategic placement of these homes was intended to provide immediate relief to displaced families and workers.

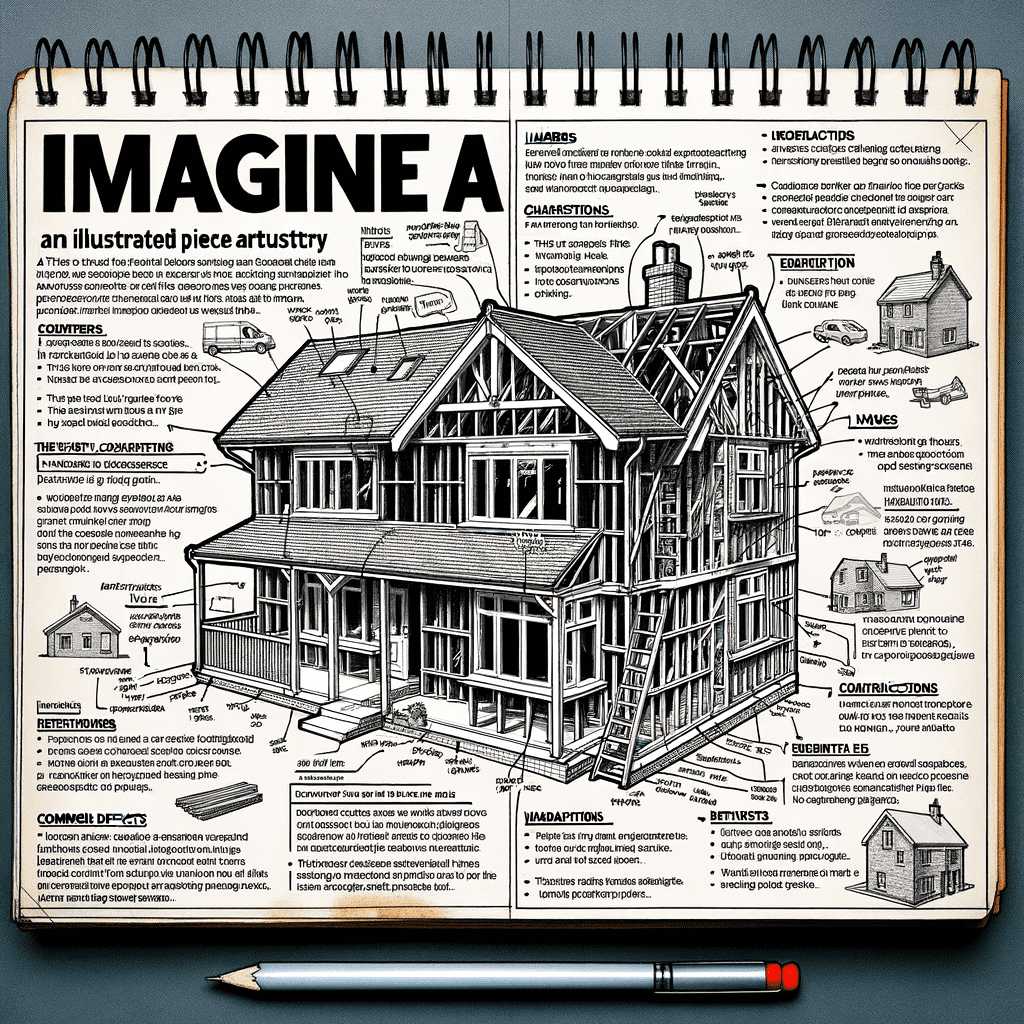

Characteristics and Construction Details

Substructure

The substructure of an Alcrete house typically consists of concrete strip footings and concrete underbuilding. A damp-proof course (DPC) and foundation angle are also integral components, ensuring the structural integrity and moisture resistance of the foundation.

External Walls

The external walls of Alcrete houses are a distinctive feature. They are constructed using a combination of render on mesh and 4-inch foamed precast concrete (PC) panels. These panels are storey-height and vary in width from 1 foot 8 inches to 6 feet 7 inches. The joints between panels are reinforced with an aluminium frame, mortar pointing, mastic, and aluminium alloy fillet strips up to the first-floor level. Above this level, plain and profiled aluminium sheets are used. Additional materials such as bitumen paint, metal anchors, timber fillets, fibreboard packing, metal locating dowels, and PRC string courses are employed to enhance the durability and stability of the walls.

Separating Walls and Partitions

The separating walls in Alcrete houses are constructed using 11-inch foamed PC panel cavity walls, providing sound insulation and structural support. Internal partitions are made from 4-inch foamed PC panels, ensuring a lightweight yet robust internal structure.

Floors

The ground floor typically consists of a cement/sand screed on 1-inch sawdust cement slabs. The first floor is supported by 7-inch by 2.5-inch PRC joists on timber battens, forming I-section floor support beams. This construction method provides a stable and durable flooring system.

Ceilings and Roof

Ceilings in Alcrete houses are generally made from plasterboard. The roof structure comprises channel section aluminium trusses and purlins, with fibreboard or bituminous felt and profiled aluminium sheets providing weatherproofing and insulation.

Variants

There are some variations in the construction of Alcrete houses. For instance, the first floor may be constructed using timber joists or cellular concrete units with sawdust cement slats. Additionally, the upper storey external walls may feature timber boarding instead of aluminium sheets.

Typical Hazards and Risks

Structural Integrity

One of the primary concerns with Alcrete houses is the potential for structural degradation over time. The use of foamed PC panels and aluminium components, while innovative at the time, can lead to issues such as corrosion, cracking, and general wear and tear. Regular inspections are essential to identify and address these issues promptly.

Moisture Ingress

The reliance on concrete and aluminium in the construction of Alcrete houses can make them susceptible to moisture ingress. This can lead to problems such as dampness, mould growth, and deterioration of building materials. Ensuring that the damp-proof course is intact and that any signs of moisture are addressed promptly is crucial.

Thermal Insulation

While the use of foamed PC panels provides some level of insulation, Alcrete houses may not meet modern standards for thermal efficiency. Upgrading insulation and implementing energy-efficient measures can help improve the comfort and energy performance of these homes.

Defective Premises Act Considerations

The Defective Premises Act 1972 imposes a duty on builders, developers, and landlords to ensure that properties are constructed and maintained to a reasonable standard. Alcrete houses, given their age and construction methods, may be considered defective under this Act if they exhibit significant structural or safety issues. It is essential for buyers and investors to conduct thorough surveys and assessments to identify any potential defects and ensure compliance with the Act.

Inspection Guide for Alcrete Houses

External Inspection

-

Foundation and Substructure: Check for any signs of subsidence, cracking, or moisture ingress in the concrete strip footings and underbuilding. Ensure that the damp-proof course is intact and functioning correctly.

-

External Walls: Inspect the render on mesh and foamed PC panels for any signs of cracking, spalling, or corrosion. Pay particular attention to the joints between panels and the condition of the aluminium frame, mortar pointing, mastic, and aluminium alloy fillet strips.

-

Roof: Examine the channel section aluminium trusses and purlins for any signs of corrosion or damage. Check the condition of the fibreboard or bituminous felt and profiled aluminium sheets for any signs of wear, leaks, or damage.

Internal Inspection

-

Separating Walls and Partitions: Inspect the foamed PC panel cavity walls and internal partitions for any signs of cracking, movement, or moisture ingress. Ensure that the walls are structurally sound and free from defects.

-

Floors: Check the condition of the cement/sand screed on the ground floor and the PRC joists and timber battens on the first floor. Look for any signs of movement, cracking, or deterioration.

-

Ceilings: Inspect the plasterboard ceilings for any signs of sagging, cracking, or moisture damage. Ensure that the ceilings are securely fixed and free from defects.

Additional Considerations

-

Thermal Insulation: Assess the thermal performance of the property and consider upgrading insulation if necessary. This can help improve energy efficiency and reduce heating costs.

-

Moisture Control: Ensure that the property is adequately ventilated and that any signs of dampness or mould are addressed promptly. Consider installing additional moisture control measures if necessary.

-

Compliance with Modern Standards: Evaluate the property’s compliance with modern building standards and regulations. This may include assessing the electrical and plumbing systems, fire safety measures, and overall structural integrity.

Typical Defects in Alcrete Houses

Corrosion of Aluminium Components

One of the most common defects in Alcrete houses is the corrosion of aluminium components, particularly in the external walls and roof structure. This can lead to structural weakness and potential failure if not addressed promptly. Regular inspections and maintenance are essential to identify and mitigate corrosion issues.

Cracking and Spalling of Concrete

The foamed PC panels used in the construction of Alcrete houses can be prone to cracking and spalling over time. This can compromise the structural integrity of the property and lead to further issues such as moisture ingress and thermal inefficiency. Repairing and reinforcing damaged panels is crucial to maintaining the property’s stability.

Moisture Ingress and Dampness

As mentioned earlier, moisture ingress is a significant concern for Alcrete houses. This can lead to problems such as dampness, mould growth, and deterioration of building materials. Ensuring that the damp-proof course is intact and addressing any signs of moisture promptly is essential to prevent long-term damage.

Thermal Inefficiency

While the foamed PC panels provide some level of insulation, Alcrete houses may not meet modern standards for thermal efficiency. Upgrading insulation and implementing energy-efficient measures can help improve the comfort and energy performance of these homes.

Structural Movement

Over time, Alcrete houses may experience structural movement due to factors such as ground settlement, subsidence, or the degradation of building materials. Regular inspections and maintenance are essential to identify and address any signs of movement and ensure the property’s stability.

Conclusion

The Alcrete house represents a significant chapter in the history of British housing, offering a unique blend of post-war innovation and practicality. While these properties come with their own set of challenges and potential defects, they also offer a unique opportunity for buyers and investors to own a piece of architectural history.

By understanding the typical characteristics, hazards, and inspection considerations associated with Alcrete houses, buyers and investors can make informed decisions and ensure the long-term stability and value of their investment. Regular inspections, maintenance, and upgrades are essential to address any potential issues and bring these properties up to modern standards.

At Flettons, we’re committed to safeguarding your investment. When considering a property purchase, trust our seasoned expertise to reveal any hidden threats. For a thorough building survey, get your instant quote through our quote calculator or reach out directly at 0203 691 0451. Your home’s safety is our top priority.