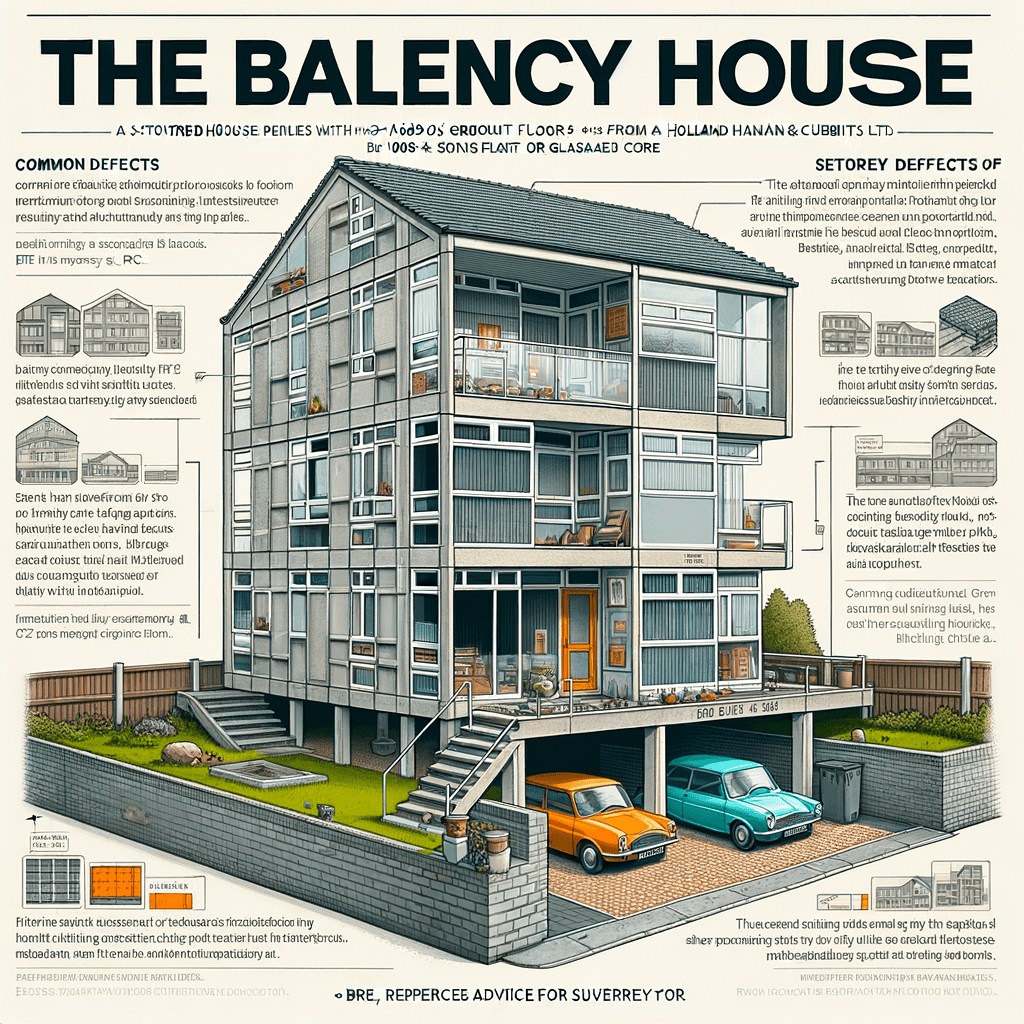

The Balency House: A Comprehensive Guide for Home Buyers and Investors

Introduction to the Balency House

The Balency House, a notable example of system-built properties in the UK, represents a significant chapter in the history of British housing. Constructed primarily during the 1960s and 1970s, these properties were designed to address the post-war housing shortage. As an expert surveyor, I will delve into the intricate details of the Balency House, providing you with a thorough understanding of its construction, typical characteristics, potential hazards, and inspection guidelines.

Historical Context and Manufacturing

Period and Location

The Balency House was predominantly built between the 1960s and 1970s, a period marked by a pressing need for rapid and cost-effective housing solutions. These properties are typically found in urban and suburban areas across the UK, where there was a high demand for affordable housing.

Manufacturers and Designers

The Balency House was manufactured by Holland & Hannan & Cubitts Ltd, a prominent construction company known for its innovative approach to building. The design of these houses was a collaborative effort, involving various architects and engineers who aimed to create functional and durable homes.

Characteristics of the Balency House

Structural Features

The Balency House is a three-storey terraced property, often featuring integral ground floor garages. This design was intended to maximize space and provide practical living solutions for families.

Roof

The roof of the Balency House is flat and typically covered with asphalt. This design choice was common during the period and aimed at reducing construction costs while providing a modern aesthetic.

External Walls

The external walls are constructed from large storey-height precast concrete (PC) panels. These panels may have a plain, sand-blasted, or scrubbed finish, or be clad with stone or glass mosaic. The use of PC panels was a hallmark of system-built properties, offering both structural integrity and ease of assembly.

Internal Walls and Partitions

The internal walls, including separating walls, are also made from storey-height PC sandwich panels with an insulating core of polystyrene or lightweight aggregate no-fines concrete. This construction method provided good thermal insulation and soundproofing.

Floors

The ground floor is typically made of concrete, while the upper floors consist of PC slabs. This robust construction ensures durability and stability.

Ceilings

Ceilings in the Balency House are usually plastered, providing a smooth and clean finish.

Potential Hazards and Risks

Structural Concerns

One of the primary concerns with the Balency House is the potential for structural issues related to the use of precast concrete. Over time, concrete can suffer from various forms of degradation, including carbonation and corrosion of the steel reinforcement.

Carbonation

Carbonation is a chemical reaction that occurs when carbon dioxide from the air penetrates the concrete and reacts with calcium hydroxide to form calcium carbonate. This process can reduce the alkalinity of the concrete, leading to the corrosion of the embedded steel reinforcement. The depth of carbonation can be assessed using guidelines provided in BRE Report BR 19.

Corrosion of Steel Reinforcement

Corrosion of the steel reinforcement is a significant risk in older concrete structures. This can lead to cracking, spalling, and ultimately, a reduction in the structural integrity of the building. Guidance on assessing and mitigating this risk can be found in BRE Digest 444, Parts 1-3.

Thermal Insulation and Energy Efficiency

While the insulating core of the PC panels provides some thermal insulation, the overall energy efficiency of the Balency House may not meet modern standards. Upgrading insulation and improving airtightness can help enhance energy performance.

Water Ingress and Dampness

Flat roofs, such as those found on the Balency House, are prone to water ingress and dampness issues. Regular maintenance and timely repairs are essential to prevent water-related damage.

Defective Premises Act and Classification

The Balency House is not classified as defective under the Defective Premises Act. However, it is essential to conduct thorough inspections to identify any potential issues and ensure the property meets current safety and habitability standards.

Inspection Guidelines for Surveyors

Pre-Inspection Preparation

Before conducting an inspection, it is crucial to gather all relevant information about the property, including historical data, previous inspection reports, and any known issues. This preparation will help you focus on critical areas and identify potential problems more effectively.

External Inspection

Roof

Inspect the flat roof for signs of wear and tear, including cracks, blisters, and ponding water. Check the condition of the asphalt covering and ensure that drainage systems are functioning correctly.

External Walls

Examine the external walls for signs of cracking, spalling, and other forms of concrete degradation. Pay particular attention to areas around windows and doors, where water ingress is more likely to occur.

Internal Inspection

Walls and Partitions

Check the internal walls and partitions for signs of movement, cracking, and dampness. Use a moisture meter to detect hidden damp issues and assess the condition of the insulation core.

Floors

Inspect the ground and upper floors for signs of settlement, cracking, and unevenness. Pay attention to any areas where the floor feels spongy or unstable, as this could indicate underlying structural issues.

Ceilings

Examine the ceilings for signs of cracking, staining, and dampness. Check for any areas where the plaster has become loose or detached.

Specialist Testing

In some cases, it may be necessary to conduct specialist testing to assess the condition of the concrete and steel reinforcement. This can include carbonation depth testing, chloride ion testing, and half-cell potential measurements.

Typical Defects and Maintenance

Common Defects

Concrete Degradation

As mentioned earlier, concrete degradation is a common issue in Balency Houses. This can manifest as cracking, spalling, and delamination of the concrete surface.

Steel Corrosion

Corrosion of the steel reinforcement can lead to significant structural issues. Look for signs of rust staining, cracking, and spalling around areas where the steel is embedded.

Water Ingress

Flat roofs are particularly susceptible to water ingress. Check for signs of dampness, staining, and mould growth on the ceilings and upper walls.

Maintenance Tips

Regular Inspections

Conduct regular inspections to identify and address issues before they become severe. Pay particular attention to the roof, external walls, and areas prone to dampness.

Timely Repairs

Carry out timely repairs to address any defects identified during inspections. This can include patching cracks, resealing the roof, and treating corroded steel reinforcement.

Upgrading Insulation

Consider upgrading the insulation in the walls and roof to improve energy efficiency and reduce heating costs.

Conclusion

The Balency House, with its distinctive design and construction, represents an important part of the UK’s housing history. While these properties offer many benefits, including robust construction and practical living spaces, they also come with potential risks and maintenance challenges. By understanding the typical characteristics, hazards, and inspection guidelines, home buyers and investors can make informed decisions and ensure the long-term safety and durability of their investment.

At Flettons, we’re committed to safeguarding your investment. When considering a property purchase, trust our seasoned expertise to reveal any hidden threats. For a thorough building survey, get your instant quote through our quote calculator or reach out directly at 0203 691 0451. Your home’s safety is our top priority.