The Bellrock House: A Comprehensive Guide for Home Buyers and Investors

Historical Context and Manufacturing Background

The Bellrock House, a distinctive property type, emerged in the 1940s, a period marked by a significant demand for housing in the UK. This demand was driven by the post-World War II housing shortage, necessitating rapid and efficient construction methods. The Bellrock House was one of the many system-built properties designed to address this need.

Manufactured by Sound City, a company known for its innovative approach to construction, the Bellrock House was designed to be both functional and aesthetically pleasing. The designers aimed to create homes that were not only quick to build but also durable and comfortable for the occupants. A total of 18 Bellrock Houses were built, making them relatively rare and unique in the UK housing market.

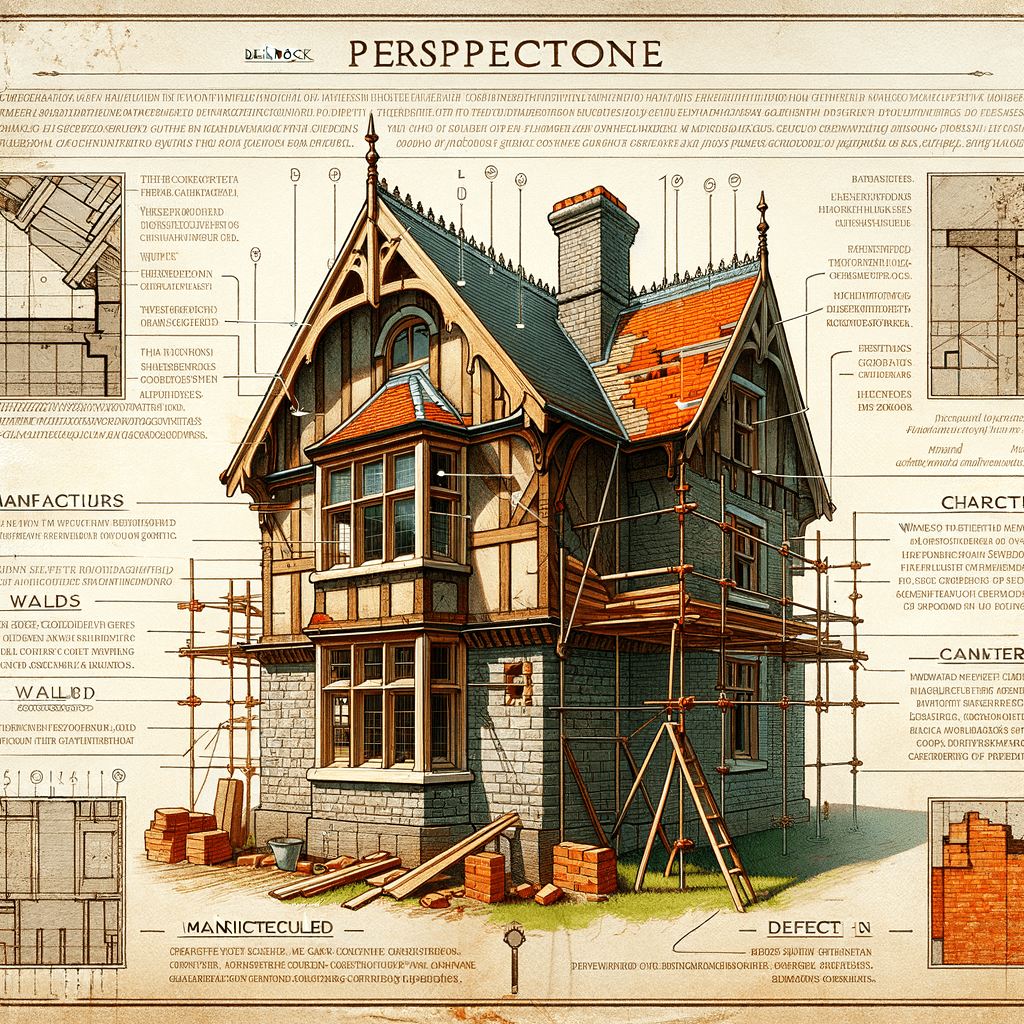

Typical Characteristics of Bellrock Houses

Architectural Features

Bellrock Houses are easily identifiable by their architectural features. They come in two main forms: chalet bungalows and two-storey semi-detached houses. One of the most striking features is the steep pitch hipped roof, which is covered with plain clay tiles. This design not only adds to the aesthetic appeal but also provides practical benefits such as efficient water drainage and increased attic space.

The external walls of Bellrock Houses are typically constructed of brick or harled throughout. This choice of materials was intended to provide both durability and a pleasing appearance. The use of brick also offers good thermal mass, helping to regulate indoor temperatures.

Construction Details

Substructure

The substructure of Bellrock Houses consists of concrete strip foundations. This type of foundation is known for its strength and stability, providing a solid base for the structure above.

External Walls

The external walls are a key feature of Bellrock Houses. They are constructed using storey-height 4″ loadbearing Bellrock hollow-cored plaster panels, which are directly clad with brick. This method of construction provides both structural integrity and an attractive exterior finish. Reinforced concrete (RC) lintels are used in the inner leaf over large openings, formed by breaking out internal webs. In the outer leaf, lintels are formed from three courses of reinforced brick.

Internal Structure

The internal structure of Bellrock Houses includes a concrete slab for the ground floor, providing a durable and stable base. The first floor is constructed using tongue-and-groove (T&G) boarding on timber joists, supported by rolled steel angles (RSAs). The ceilings are made of recessed edge plasterboard, which offers a smooth and clean finish.

Roof

The roof structure consists of timber rafters supported by a timber softwood wall plate. This traditional method of roof construction provides both strength and flexibility, allowing for the steep pitch design that is characteristic of Bellrock Houses.

Typical Hazards and Risks

Structural Concerns

One of the primary concerns with Bellrock Houses is the potential for structural issues, particularly related to the reinforced concrete elements. Over time, reinforced concrete can suffer from corrosion of the steel reinforcement, leading to weakening of the structure. This is particularly a risk in properties that have not been well-maintained or have been exposed to harsh environmental conditions.

Damp and Moisture Ingress

Due to the age of these properties, damp and moisture ingress can be a common issue. This can be exacerbated by the use of hollow-cored plaster panels in the external walls, which may allow moisture to penetrate if not properly sealed and maintained. Damp can lead to a range of problems, including mould growth, timber decay, and damage to internal finishes.

Thermal Efficiency

While the brick cladding provides good thermal mass, the overall thermal efficiency of Bellrock Houses may not meet modern standards. This can result in higher heating costs and reduced comfort for occupants. Upgrading insulation and improving airtightness can help to address these issues.

Defective Premises Act Considerations

The Defective Premises Act 1972 imposes a duty on builders, developers, and landlords to ensure that properties are constructed and maintained to a reasonable standard. While Bellrock Houses were built to the standards of their time, they may not meet modern building regulations and standards. As such, they could be considered defective under the Act if they pose a risk to the health and safety of occupants.

It is important for potential buyers and investors to be aware of this and to ensure that any necessary repairs and upgrades are carried out to bring the property up to current standards. This may include addressing structural issues, improving thermal efficiency, and ensuring that the property is free from damp and moisture ingress.

Inspection and Assessment Guide

Pre-Inspection Preparation

Before conducting an inspection of a Bellrock House, it is important to gather as much information as possible about the property. This includes reviewing any available documentation, such as previous survey reports, maintenance records, and planning permissions. It is also useful to have a copy of the original construction plans, if available, to understand the layout and construction details.

External Inspection

Roof

Start by inspecting the roof for any signs of damage or wear. Look for missing or broken tiles, as well as any signs of sagging or unevenness. Check the condition of the timber rafters and wall plate, and look for any signs of rot or insect infestation.

Walls

Examine the external walls for any signs of cracking, bulging, or movement. Pay particular attention to the areas around openings, such as windows and doors, where the RC lintels are located. Look for any signs of corrosion or deterioration of the reinforced concrete elements.

Damp and Moisture

Check for any signs of damp or moisture ingress, such as staining, efflorescence, or mould growth. Use a moisture meter to assess the moisture levels in the walls and floors. Pay particular attention to the base of the walls, where rising damp may be an issue.

Internal Inspection

Floors

Inspect the ground floor slab for any signs of cracking or movement. Check the condition of the first floor T&G boarding and timber joists, and look for any signs of rot or insect infestation. Pay particular attention to the areas around the RSAs, as these can be prone to corrosion.

Walls and Partitions

Examine the internal walls and partitions for any signs of cracking, movement, or damp. Check the condition of the plasterboard ceilings, and look for any signs of sagging or water damage.

Thermal Efficiency

Assess the thermal efficiency of the property by checking the insulation levels in the walls, floors, and roof. Look for any signs of draughts or air leakage, and consider using a thermal imaging camera to identify any areas of heat loss.

Typical Defects and Maintenance Tips

Reinforced Concrete Corrosion

As mentioned earlier, corrosion of the steel reinforcement in the reinforced concrete elements can be a significant issue in Bellrock Houses. Regular inspections and maintenance are essential to identify and address any signs of corrosion before they lead to structural problems. This may involve removing and replacing damaged concrete, as well as applying protective coatings to prevent further corrosion.

Damp and Moisture Control

To prevent damp and moisture ingress, it is important to ensure that the property is well-sealed and maintained. This includes repairing any damaged or missing roof tiles, ensuring that gutters and downpipes are clear and functioning properly, and applying waterproof coatings to the external walls. Installing a damp-proof course (DPC) and ensuring that it is in good condition can also help to prevent rising damp.

Insulation and Energy Efficiency

Improving the insulation and energy efficiency of Bellrock Houses can help to reduce heating costs and improve comfort for occupants. This may involve adding insulation to the walls, floors, and roof, as well as upgrading windows and doors to double or triple glazing. Sealing any gaps and draughts can also help to improve airtightness and reduce heat loss.

Timber Maintenance

Regular maintenance of the timber elements, such as the rafters, wall plate, and floor joists, is essential to prevent rot and insect infestation. This may involve treating the timber with preservatives, as well as repairing or replacing any damaged or decayed sections.

Conclusion

The Bellrock House is a unique and distinctive property type that offers both challenges and opportunities for home buyers and investors. While these properties were built to address the housing shortage of the 1940s, they may not meet modern standards and can be prone to a range of issues, including structural concerns, damp and moisture ingress, and poor thermal efficiency.

However, with careful inspection, maintenance, and upgrading, Bellrock Houses can be transformed into comfortable and desirable homes. By understanding the typical characteristics, hazards, and risks associated with these properties, buyers and investors can make informed decisions and ensure that their investment is protected.

At Flettons, we’re committed to safeguarding your investment. When considering a property purchase, trust our seasoned expertise to reveal any hidden threats. For a thorough building survey, get your instant quote through our quote calculator or reach out directly at 0203 691 0451. Your home’s safety is our top priority.