The Blackborrow House: A Comprehensive Guide for Home Buyers and Investors

Historical Context and Manufacturing Background

The Blackborrow house, a notable example of system-built properties, emerged in the 1940s as a response to the urgent need for housing post-World War II. Designed by H.J. Blackborrow and A. MacDonald, these properties were part of a broader movement to quickly and efficiently address the housing shortage. The Blackborrow system was a pioneering approach in the construction industry, leveraging pre-cast concrete (PC) panels to expedite the building process.

Manufacturers and Designers

The Blackborrow house was primarily manufactured by companies specializing in pre-cast concrete technology. The designers, H.J. Blackborrow and A. MacDonald, were instrumental in developing the system that allowed for rapid assembly and robust construction. Their innovative approach set a precedent for future system-built properties.

Period and Locations

Constructed predominantly in the 1940s, Blackborrow houses can be found in various locations across the UK. These properties were typically built in suburban areas, providing affordable housing solutions for families. The exact number of Blackborrow houses built remains uncertain, but their presence is still notable in many communities.

Characteristics and Identification

Architectural Features

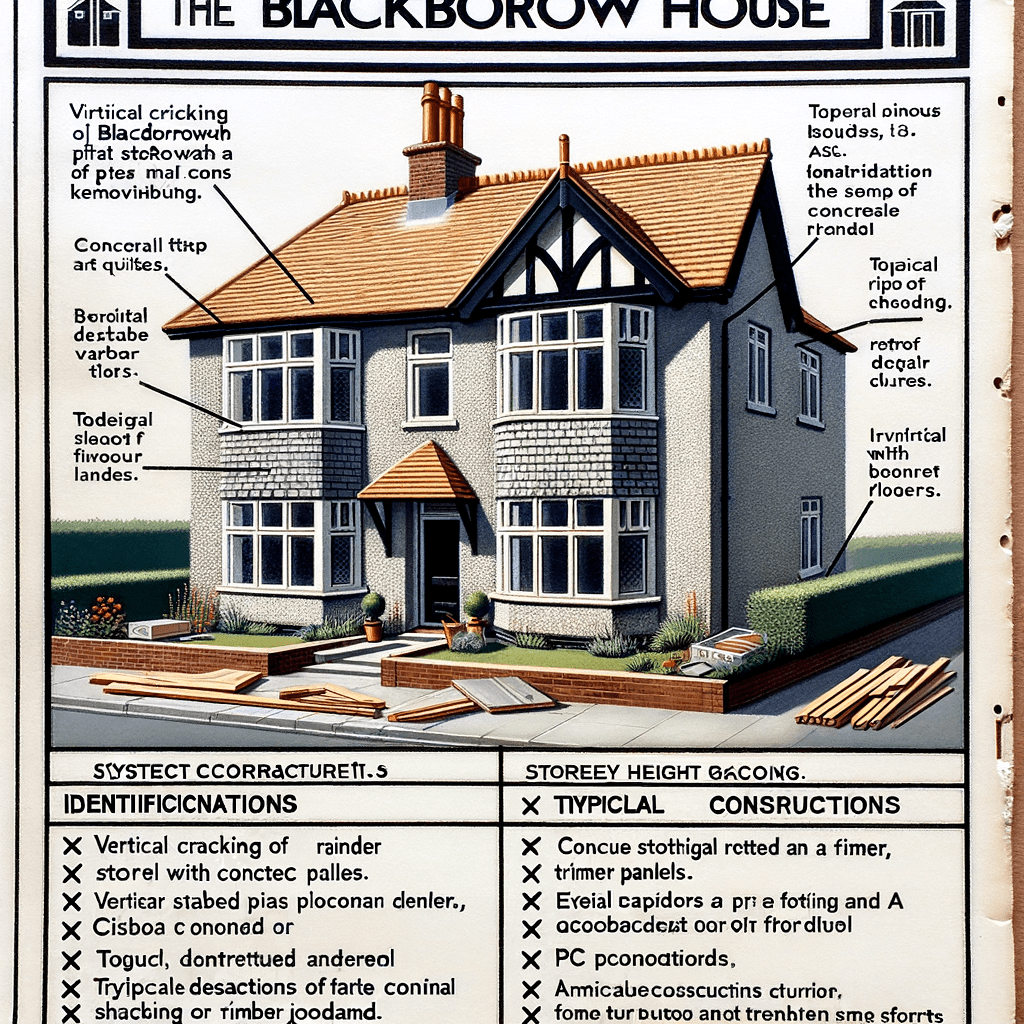

Blackborrow houses are easily identifiable by their distinct architectural features. These two-storey semi-detached houses boast a steep pitch hipped roof covered with concrete tiles. The external walls are composed of storey-height PC panels, which may feature exposed shingle or decorative finishes. These characteristics make the Blackborrow house a unique and recognizable property type.

Construction Details

Substructure

The substructure of a Blackborrow house includes concrete strip footings, concrete underbuilding, and a concrete slab. A damp-proof course (DPC) is also integrated to prevent moisture ingress.

External Walls

The external walls are constructed using 10-inch storey-height hollow PC panels. These panels consist of an outer leaf of 2-inch dense concrete, a 4.5-inch cavity, and an inner leaf of foamed concrete joined by 3-inch webs. Weep holes are incorporated to allow for moisture drainage. The panels are connected along vertical edges by two mild steel (MS) hooks, one at the top and bottom of each panel, engaging on loops protruding from adjoining panels into vertical edge rebates. A timber wall plate is used to secure the structure.

Separating Wall

The separating wall is a 4-inch foamed slag concrete cavity wall located in external wall panel recesses. In the roof space, this wall is 9 inches thick, providing additional insulation and structural integrity.

Partitions

The ground floor partitions are not well-documented, but the first floor partitions are made of breeze blocks. The ground floor spine wall consists of storey-height foamed slag PC panels.

Floors

The ground floor is constructed of concrete, while the first floor features timber boarding on timber joists located in pockets formed in the lower edge of the first-floor panels on an MS bearing bar.

Ceilings and Roof

Ceilings are typically made of plasterboard. The roof structure includes timber rafters and purlins, covered with concrete tiles.

Variants

Some Blackborrow houses feature external walls with exposed shingle finishes or concrete treated while still ‘green’ to provide a variety of decorative finishes. These variants add a unique aesthetic appeal to the properties.

Typical Hazards and Risks

Structural Issues

One of the primary concerns with Blackborrow houses is the potential for structural issues. Vertical cracking of render at quoins and diagonal and vertical cracking of PC panels are common defects. These cracks can compromise the structural integrity of the property and may require significant repairs.

Moisture Ingress

Despite the inclusion of a DPC, moisture ingress can still be a problem in Blackborrow houses. Weep holes are designed to mitigate this issue, but they can become blocked or ineffective over time. Regular maintenance and inspection are essential to prevent moisture-related problems.

Thermal Insulation

The thermal insulation properties of Blackborrow houses may not meet modern standards. The foamed concrete used in the construction provides some insulation, but additional measures may be necessary to improve energy efficiency and reduce heating costs.

Defective Premises Act

Blackborrow houses are not typically classified as defective under the Defective Premises Act. However, the presence of structural issues and other defects can still pose significant risks to occupants. It is crucial to conduct thorough inspections and address any identified problems promptly.

Inspection Guide for Surveyors

Exterior Inspection

- Roof: Inspect the steep pitch hipped roof for any signs of damage or wear. Check the condition of the concrete tiles and ensure that the timber rafters and purlins are in good condition.

- Walls: Examine the external walls for vertical and diagonal cracking. Pay particular attention to the render at quoins and the PC panels. Look for any signs of moisture ingress or damage to the weep holes.

- Foundations: Assess the condition of the concrete strip footings and underbuilding. Check for any signs of settlement or movement that could indicate foundation issues.

Interior Inspection

- Walls and Partitions: Inspect the internal walls and partitions for any signs of cracking or damage. Pay attention to the separating wall and ensure that it is structurally sound.

- Floors: Check the condition of the ground floor concrete and the first-floor timber boarding and joists. Look for any signs of sagging or damage that could indicate structural problems.

- Ceilings: Examine the plasterboard ceilings for any signs of cracking or water damage. Ensure that the roof structure is in good condition and free from leaks.

Moisture and Insulation

- Damp-Proof Course: Verify the effectiveness of the DPC and check for any signs of moisture ingress. Ensure that the weep holes are clear and functioning properly.

- Insulation: Assess the thermal insulation properties of the property. Consider recommending additional insulation measures if the existing insulation is insufficient.

Common Defects and Maintenance Tips

Cracking

Cracking is a common issue in Blackborrow houses, particularly vertical cracking of render at quoins and diagonal and vertical cracking of PC panels. Regular inspections and prompt repairs are essential to prevent further damage.

Moisture Ingress

Moisture ingress can lead to significant problems, including mould growth and structural damage. Ensure that the DPC is effective and that weep holes are clear. Consider installing additional moisture barriers if necessary.

Insulation

Improving the thermal insulation of a Blackborrow house can enhance energy efficiency and reduce heating costs. Consider adding insulation to the walls, roof, and floors to improve the property’s overall performance.

Roof Maintenance

Regular roof maintenance is crucial to prevent leaks and damage. Inspect the condition of the concrete tiles and timber rafters and purlins. Replace any damaged or worn components promptly.

Conclusion

The Blackborrow house represents a significant chapter in the history of UK housing. These system-built properties, designed by H.J. Blackborrow and A. MacDonald, provided a rapid and efficient solution to the post-war housing crisis. While they offer unique architectural features and construction methods, they also come with specific challenges and risks.

For home buyers and investors, understanding the characteristics and potential issues of Blackborrow houses is essential. Regular inspections, maintenance, and prompt repairs can help preserve the structural integrity and value of these properties. At Flettons, we’re committed to safeguarding your investment. When considering a property purchase, trust our seasoned expertise to reveal any hidden threats. For a thorough building survey, get your instant quote through our quote calculator or reach out directly at 0203 691 0451. Your home’s safety is our top priority.