The Broadmead House: A Comprehensive Guide for Home Buyers and Investors

Historical Context and Background

The Broadmead house, a distinctive property type, was manufactured by Broadmead Products Ltd and designed by B W H Scott. These properties were predominantly built in the 1940s, a period marked by a significant demand for housing solutions in the UK. The Broadmead house is a classic example of system-built properties, which were developed to address the urgent need for quick and cost-effective housing post-World War II.

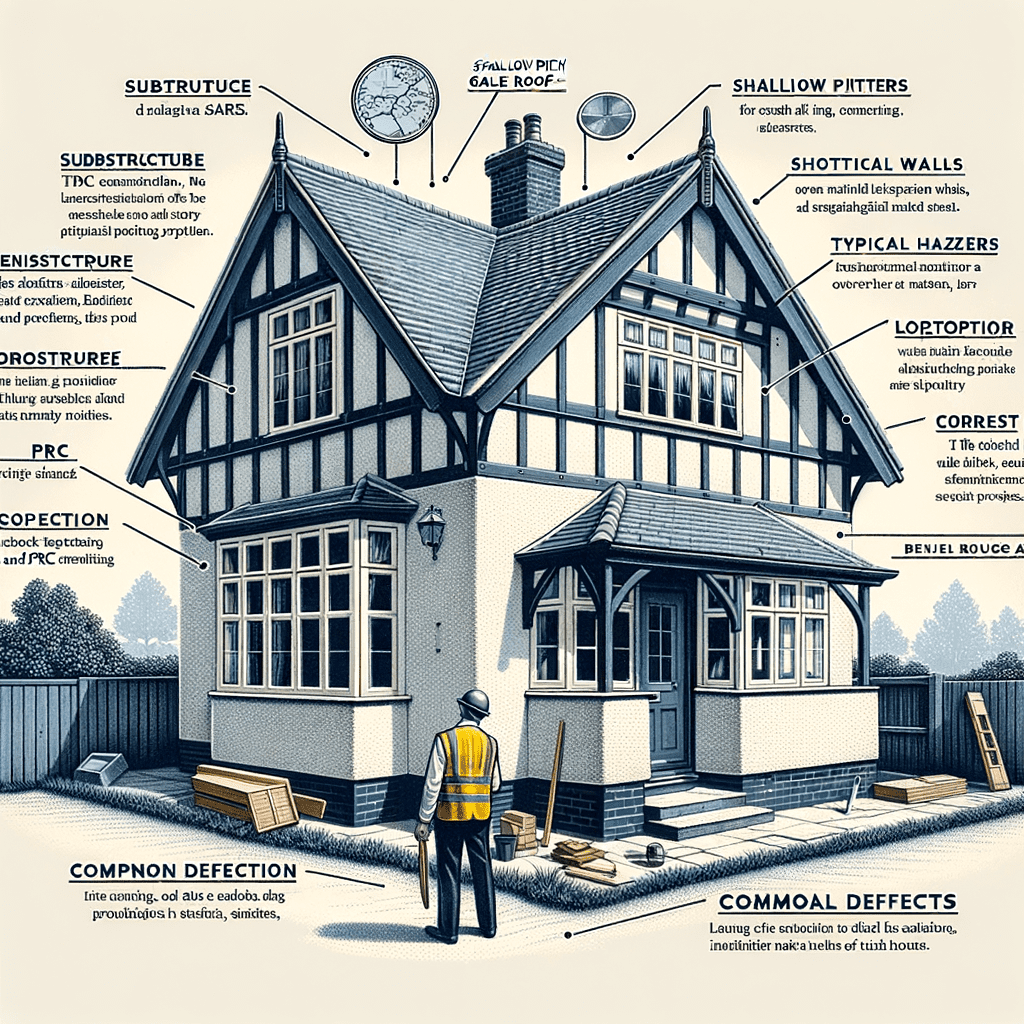

These houses are typically found in suburban areas and are easily identifiable by their unique construction features. They are predominantly bungalows with shallow pitch gable roofs covered with concrete, asbestos cement slates, or profiled sheets. The external walls are constructed using storey-height precast reinforced concrete (PRC) panels set in a zig-zag formation, and the gable apex is often made of asbestos cement sheets. PRC capping beams are present at the eaves level, and the corners are splayed with PRC corner columns.

Manufacturers and Designers

Broadmead Products Ltd, the manufacturer behind these houses, was a key player in the post-war housing boom. The designer, B W H Scott, was instrumental in creating a design that was both functional and economical. The use of PRC panels was a significant innovation at the time, allowing for rapid construction and reduced costs.

Typical Characteristics and Hazards

Construction Details

Substructure

The substructure of Broadmead houses typically consists of concrete strip footings and concrete underbuilding. This provides a solid foundation for the structure, ensuring stability and durability.

Frame

The main frame is constructed using 8″ x 8″ storey-height PRC corner columns and 5″ x 5″ storey-height PRC intermediate posts. These components provide the necessary structural support for the building.

External Walls

The external walls are made of 12″ x 1 1/2″ storey-height dished PRC panels set in a zig-zag formation. These panels are cavity-filled and lined with fibreboard on timber battens attached to wooden blocks cast into the panels. PRC capping units, measuring 3″ x 6 1/2″, are fixed to the PRC panels by dowels.

Partitions

Internal partitions are typically timber stud lined with fibreboard. Some partitions are lined to dado height with glazed asbestos cement sheets, providing additional durability and fire resistance.

Ground Floor

The ground floor consists of timber boarding on timber battens on concrete, providing a stable and durable flooring solution.

Roof

The roof structure includes steel trusses, timber trusses adjacent to the gable wall, timber purlins, and asbestos cement slates. Variants of the roof include PC roof panels and roof covers made of asbestos cement sheets.

Typical Hazards and Risks

Asbestos

One of the primary hazards associated with Broadmead houses is the presence of asbestos in the roofing materials and internal partitions. Asbestos is a known health hazard, and its presence requires careful management and, in some cases, professional removal.

PRC Panel Deterioration

The PRC panels used in the construction of Broadmead houses are prone to cracking, particularly at the vertical joints between panels. This can lead to structural issues and requires regular inspection and maintenance.

Corrosion of Steel Reinforcement

The steel reinforcement within the PRC panels is susceptible to corrosion, particularly in areas with high moisture levels. This can compromise the structural integrity of the building and necessitates regular monitoring and maintenance.

Defective Premises Act Considerations

Broadmead houses are not typically classified as defective under the Defective Premises Act. However, the presence of asbestos and the potential for PRC panel deterioration and steel reinforcement corrosion are significant concerns that need to be addressed. It is essential for potential buyers and investors to be aware of these issues and to ensure that thorough inspections are carried out before purchasing a Broadmead house.

Inspection and Assessment Guide

Cracking of Vertical Joints

One of the most common defects in Broadmead houses is the cracking of vertical joints between PRC panels. This can be caused by a variety of factors, including thermal expansion and contraction, settlement of the building, and moisture ingress. When inspecting a Broadmead house, it is essential to check for any signs of cracking and to assess the severity of the damage.

Corrosion of Steel Reinforcement

The steel reinforcement within the PRC panels is prone to corrosion, particularly in areas with high moisture levels. This can lead to spalling of the concrete and a reduction in the structural integrity of the building. When inspecting a Broadmead house, it is important to check for any signs of corrosion, such as rust stains or spalling concrete, and to assess the extent of the damage.

Asbestos Management

Asbestos is a significant health hazard, and its presence in Broadmead houses requires careful management. When inspecting a Broadmead house, it is essential to identify any areas where asbestos may be present, such as in the roofing materials or internal partitions. If asbestos is found, it is important to ensure that it is properly managed and, if necessary, professionally removed.

General Maintenance and Repairs

Regular maintenance and repairs are essential to ensure the longevity and safety of Broadmead houses. This includes regular inspections of the PRC panels and steel reinforcement, as well as the management of any asbestos-containing materials. It is also important to carry out any necessary repairs promptly to prevent further deterioration of the building.

Typical Construction Details

Roof

The roof of a Broadmead house is typically constructed using steel trusses, timber trusses adjacent to the gable wall, timber purlins, and asbestos cement slates. Variants of the roof include PC roof panels and roof covers made of asbestos cement sheets. The shallow pitch gable roof is a distinctive feature of Broadmead houses and provides a unique aesthetic.

Walls

The external walls of Broadmead houses are constructed using 12″ x 1 1/2″ storey-height dished PRC panels set in a zig-zag formation. These panels are cavity-filled and lined with fibreboard on timber battens attached to wooden blocks cast into the panels. PRC capping units, measuring 3″ x 6 1/2″, are fixed to the PRC panels by dowels. The gable apex is typically made of asbestos cement sheets.

Floors

The ground floor of a Broadmead house consists of timber boarding on timber battens on concrete. This provides a stable and durable flooring solution. The first floor is not applicable, as Broadmead houses are typically bungalows.

Main Frame

The main frame of a Broadmead house is constructed using 8″ x 8″ storey-height PRC corner columns and 5″ x 5″ storey-height PRC intermediate posts. These components provide the necessary structural support for the building.

Typical Defects and Maintenance

Cracking of PRC Panels

One of the most common defects in Broadmead houses is the cracking of PRC panels, particularly at the vertical joints. This can be caused by a variety of factors, including thermal expansion and contraction, settlement of the building, and moisture ingress. Regular inspections are essential to identify any signs of cracking and to assess the severity of the damage.

Corrosion of Steel Reinforcement

The steel reinforcement within the PRC panels is prone to corrosion, particularly in areas with high moisture levels. This can lead to spalling of the concrete and a reduction in the structural integrity of the building. Regular inspections are essential to identify any signs of corrosion, such as rust stains or spalling concrete, and to assess the extent of the damage.

Asbestos Management

Asbestos is a significant health hazard, and its presence in Broadmead houses requires careful management. Regular inspections are essential to identify any areas where asbestos may be present, such as in the roofing materials or internal partitions. If asbestos is found, it is important to ensure that it is properly managed and, if necessary, professionally removed.

General Maintenance and Repairs

Regular maintenance and repairs are essential to ensure the longevity and safety of Broadmead houses. This includes regular inspections of the PRC panels and steel reinforcement, as well as the management of any asbestos-containing materials. It is also important to carry out any necessary repairs promptly to prevent further deterioration of the building.

Conclusion

The Broadmead house is a distinctive and historically significant property type that offers a unique aesthetic and functional design. However, potential buyers and investors need to be aware of the typical hazards and risks associated with these properties, including the presence of asbestos, the potential for PRC panel deterioration, and the risk of steel reinforcement corrosion.

Regular inspections and maintenance are essential to ensure the longevity and safety of Broadmead houses. By understanding the typical construction details and common defects, buyers and investors can make informed decisions and take the necessary steps to safeguard their investment.

At Flettons, we’re committed to safeguarding your investment. When considering a property purchase, trust our seasoned expertise to reveal any hidden threats. For a thorough building survey, get your instant quote through our quote calculator or reach out directly at 0203 691 0451. Your home’s safety is our top priority.