The Concrete Frames House: A Comprehensive Guide for UK Home Buyers and Investors

Historical Context and Manufacturing Details

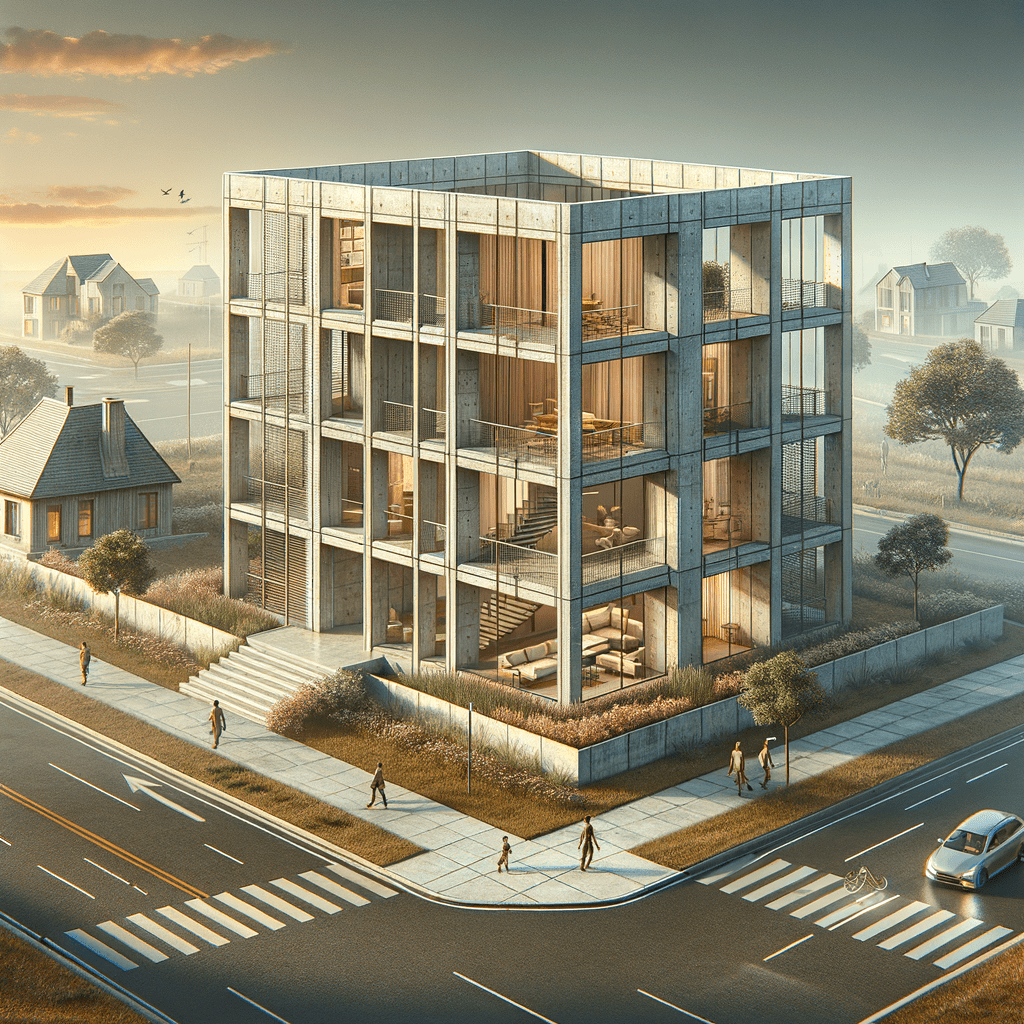

Concrete Frames houses, a unique and rare type of property, were manufactured by Concrete Frames Ltd in 1945. Only two of these properties were ever built, making them an intriguing subject for both home buyers and property investors. These houses are typically found in specific locations where experimental or prototype housing was being tested post-World War II. The manufacturer, Concrete Frames Ltd, was also the designer, ensuring a cohesive vision from conception to construction.

Identification Characteristics

Concrete Frames houses are easily identifiable by their distinct architectural features. They are 2-storey semi-detached houses with a medium pitch hipped roof covered with profiled asbestos cement tiles. The external walls are made of Precast Reinforced Concrete (PRC) panels, which were a common material choice during the mid-20th century for their durability and cost-effectiveness.

Alternative Names

While these houses are primarily known as Concrete Frames houses, they do not have widely recognized alternative names due to their limited production.

Typical Characteristics and Construction Details

Understanding the construction details of Concrete Frames houses is crucial for potential buyers and investors. Here, we delve into the various components that make up these unique properties.

Substructure

The substructure of Concrete Frames houses consists of a reinforced concrete (RC) raft underbuilding, which is thickened under external and load-bearing walls. This design choice provides a stable and robust foundation, essential for the longevity of the property. A slate damp-proof course (DPC) is also included to prevent moisture ingress from the ground.

Main Frame

The main frame is constructed from storey-height RC columns, with additional RC posts at corners, and around window and door openings. This framework provides the structural integrity necessary to support the weight of the building and resist various environmental stresses.

External Walls

The external walls are composed of 10 1/2″ x 4″ flanged channel section PRC panels, creating a cavity that is filled with 2″ clinker aggregate precast concrete (PC) blocks. PRC lintels are used over openings such as windows and doors, ensuring that these areas are adequately supported.

Partitions and Separating Walls

Internal partitions are made from 3″ clinker aggregate PC blocks, while separating walls between semi-detached units consist of PRC channel section panels, a cavity, and clinker aggregate PC blocks lined with plasterboard. This construction method provides both structural support and sound insulation between units.

Floors

The ground floor is constructed from concrete, providing a solid and durable base. The first floor features PRC T-beams, which are known for their strength and ability to span large distances without requiring additional support.

Ceilings

Ceilings in Concrete Frames houses are made from wood-fibre boarding mounted on timber battens, with galvanised hoop iron fixings used for first-floor ceilings. This combination of materials ensures a sturdy and long-lasting ceiling structure.

Roof

The roof is constructed using PRC purlins, a PRC ridge beam, PRC common rafters, and PRC ceiling joists. The roof covering consists of profiled asbestos cement tiles, which were a popular choice in the mid-20th century due to their durability and fire-resistant properties.

Typical Hazards and Risks

While Concrete Frames houses have many positive attributes, there are also several hazards and risks associated with this type of construction. Understanding these potential issues is crucial for anyone considering purchasing or investing in such a property.

Asbestos

One of the most significant risks associated with Concrete Frames houses is the presence of asbestos in the roof tiles. Asbestos was commonly used in construction during the mid-20th century due to its fire-resistant properties. However, it is now known to be a hazardous material that can cause serious health issues if disturbed. It is essential to have a professional asbestos survey conducted before purchasing a Concrete Frames house.

Corrosion of Steel Reinforcement

The steel reinforcement within the concrete can be susceptible to corrosion, particularly if the concrete has not been adequately maintained. Corrosion of the steel can lead to structural weaknesses and potential failure. Regular inspections and maintenance are essential to ensure the longevity of the property.

Carbonation

Carbonation is a process where carbon dioxide from the air penetrates the concrete and reacts with the calcium hydroxide within it, forming calcium carbonate. This process can reduce the alkalinity of the concrete, leading to the corrosion of the steel reinforcement. It is crucial to monitor carbonation depths and take appropriate measures to mitigate its effects.

Moisture Ingress

Moisture ingress can be a significant issue in Concrete Frames houses, particularly if the damp-proof course (DPC) has failed or if there are cracks in the concrete. Moisture can lead to various problems, including mould growth, deterioration of building materials, and potential health issues for occupants.

Defective Premises Act

Concrete Frames houses are not classed as defective under the Defective Premises Act. However, due to their unique construction and potential hazards, it is essential to conduct thorough inspections and maintenance to ensure their continued safety and habitability.

Inspection and Assessment Guide

For surveyors and potential buyers, conducting a thorough inspection of a Concrete Frames house is crucial. Here are some key areas to focus on during the inspection process:

External Inspection

- Roof: Check for any signs of damage or deterioration in the asbestos cement tiles. Look for any missing or broken tiles and assess the overall condition of the roof structure.

- Walls: Inspect the PRC panels for any cracks, spalling, or signs of corrosion. Pay particular attention to areas around windows and doors where the PRC lintels are located.

- Damp-Proof Course (DPC): Ensure that the slate DPC is intact and functioning correctly. Look for any signs of rising damp or moisture ingress.

Internal Inspection

- Floors: Check the condition of the concrete ground floor and the PRC T-beams on the first floor. Look for any signs of cracking or movement.

- Ceilings: Inspect the wood-fibre boarding and timber battens for any signs of damage or deterioration. Ensure that the galvanised hoop iron fixings are secure.

- Partitions and Separating Walls: Assess the condition of the clinker aggregate PC blocks and the PRC channel section panels. Look for any signs of cracking or movement.

Structural Integrity

- Steel Reinforcement: Check for any signs of corrosion in the steel reinforcement. This may involve taking core samples of the concrete and conducting laboratory tests to assess the extent of any corrosion.

- Carbonation: Measure the carbonation depth in the concrete to determine if it has reached the steel reinforcement. If necessary, take appropriate measures to mitigate the effects of carbonation.

Asbestos Survey

- Asbestos: Conduct a professional asbestos survey to identify any asbestos-containing materials within the property. If asbestos is found, ensure that it is managed and, if necessary, removed by a licensed asbestos removal contractor.

Maintenance and Repair

Regular maintenance and timely repairs are essential to ensure the longevity and safety of Concrete Frames houses. Here are some key maintenance and repair considerations:

Roof Maintenance

- Asbestos Cement Tiles: Regularly inspect the roof tiles for any signs of damage or deterioration. Replace any missing or broken tiles promptly to prevent water ingress.

- Roof Structure: Ensure that the PRC purlins, ridge beam, common rafters, and ceiling joists are in good condition. Address any signs of damage or deterioration promptly.

Wall Maintenance

- PRC Panels: Regularly inspect the PRC panels for any signs of cracking, spalling, or corrosion. Address any issues promptly to prevent further deterioration.

- Damp-Proof Course (DPC): Ensure that the slate DPC is functioning correctly. Address any signs of rising damp or moisture ingress promptly.

Structural Maintenance

- Steel Reinforcement: Regularly inspect the steel reinforcement for any signs of corrosion. If corrosion is detected, take appropriate measures to address the issue, such as applying corrosion inhibitors or conducting repairs.

- Carbonation: Monitor the carbonation depth in the concrete and take appropriate measures to mitigate its effects, such as applying surface treatments or conducting repairs.

Asbestos Management

- Asbestos: If asbestos-containing materials are present, ensure that they are managed in accordance with current regulations. If necessary, have the asbestos removed by a licensed asbestos removal contractor.

Conclusion

Concrete Frames houses are a unique and rare type of property with distinct architectural features and construction methods. While they offer many positive attributes, there are also several potential hazards and risks associated with this type of construction. Understanding these potential issues and conducting thorough inspections and maintenance are crucial for anyone considering purchasing or investing in a Concrete Frames house.

At Flettons, we’re committed to safeguarding your investment. When considering a property purchase, trust our seasoned expertise to reveal any hidden threats. For a thorough building survey, get your instant quote through our quote calculator or reach out directly at 0203 691 0451. Your home’s safety is our top priority.