The Cornish Unit Type II House: A Comprehensive Guide for Home Buyers and Investors

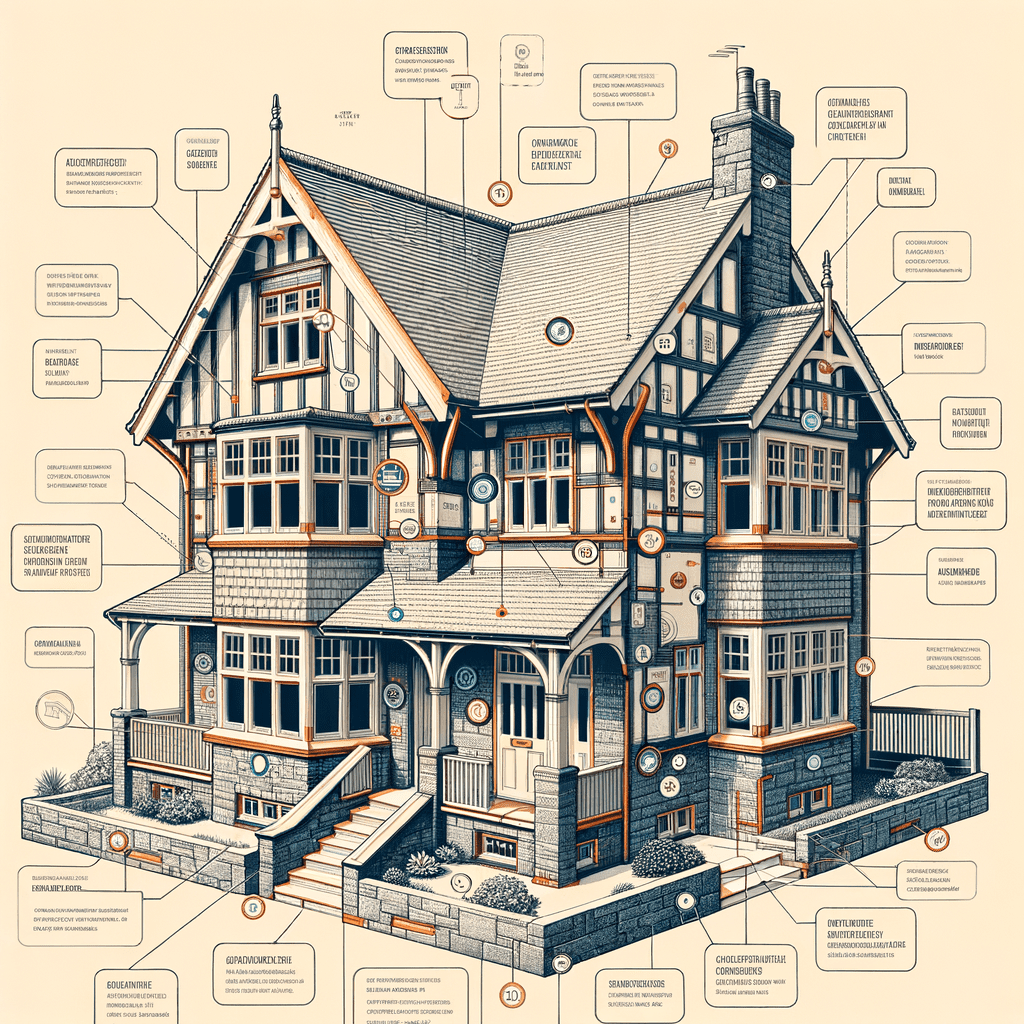

Overview of the Cornish Unit Type II House

The Cornish Unit Type II house is a notable example of post-war British architecture, designed to address the urgent housing needs of the mid-20th century. These properties were primarily constructed between 1954 and the mid-1960s, with approximately 30,000 units built, including both Type I and Type II variants. The Cornish Unit Type II houses are predominantly found in the UK, particularly in areas where rapid housing development was necessary to accommodate the growing population.

Manufacturers and Designers

The Cornish Unit Type II houses were manufactured by two main companies: Central Cornwall Concrete & Artificial Stone Co. and Selleck Nicholls & Co. The design of these houses was spearheaded by architects A E Beresford and R Tonkin, who aimed to create a cost-effective and efficient housing solution using prefabricated reinforced concrete (PRC) technology.

Typical Characteristics of Cornish Unit Type II Houses

Structural Features

Cornish Unit Type II houses are typically two-storey semi-detached properties. They are easily identifiable by their medium pitch hipped or gable roofs covered with tiles. The external walls are constructed using storey-height PRC columns and horizontal precast concrete (PC) panels. These houses were designed to be both functional and durable, although they have since been identified as having certain structural vulnerabilities.

Construction Details

Substructure

- Footings: Concrete strip footings provide the foundation for the house.

- Underbuilding: Concrete block underbuilding supports the structure above.

- Damp Proof Course (DPC): A DPC is included to prevent moisture from rising through the walls.

External Walls

- Plinth: A concrete plinth forms the base of the external walls.

- PRC Columns: The first floor level is supported by 6 7/8″ x 4″ PRC columns, while the upper levels use 5″ x 4″ PRC columns.

- PC Panels: Tapered PC panels measuring 37 3/8″ x 24″ are used in the construction of the walls.

- Cavity and Insulation: The walls feature a cavity with foil-backed honeycomb plasterboard on the first floor and foil-backed plasterboard on timber battens above.

- Additional Features: ‘Starter stone’ PC units, a string course, and PC lintels at the first floor level, along with steel tie rods and a timber eaves runner bolted to the top of the PRC columns.

Internal Walls

- Separating Wall: A 9″ concrete block or brick wall separates the two semi-detached units.

- Loadbearing Partitions: Internal loadbearing walls are constructed from 4″ dense PC block.

- Non-loadbearing Partitions: Non-loadbearing walls are made from 4″ clinker PC block.

Floors

- Ground Floor: Constructed from concrete.

- First Floor: Features tongue and groove (T&G) boarding on timber joists.

- Ceilings: Plasterboard ceilings are used throughout the house.

Roof

- Structure: The roof is supported by timber rafters and purlins.

- Covering: Concrete tiles are used to cover the roof.

Variants

Some Cornish Unit Type II houses feature non-loadbearing partitions made from timber stud lined with plasterboard. Additionally, tile cladding may be present on the upper storeys of certain variants.

Typical Hazards and Risks

Structural Defects

One of the primary concerns with Cornish Unit Type II houses is the potential for structural defects, particularly related to the PRC columns and panels. Over time, the steel reinforcement within the concrete can corrode, leading to a loss of structural integrity. This issue is exacerbated by the fact that these houses were not investigated by the Building Research Establishment (BRE) at the time of construction.

Designated Defective

Under the Housing Defects Act 1984, Cornish Unit Type II houses are designated as defective. This classification means that the properties are considered to have inherent structural issues that could affect their safety and longevity. As a result, buyers and investors should exercise caution and seek professional advice before purchasing such properties.

Inspection and Assessment

Guidance for Surveyors

When inspecting a Cornish Unit Type II house, surveyors should refer to the following BRE reports for guidance on assessing the durability of reinforced concrete:

- Corrosion of Steel in Concrete (BRE Digest 444, Parts 1–3)

- Repair and Maintenance of Reinforced Concrete (BR 254)

- Carbonation Depths in Structural-Quality Concrete (BR 19)

Key Areas to Inspect

External Walls

- PRC Columns and PC Panels: Check for signs of cracking, spalling, or corrosion in the PRC columns and PC panels. These issues can indicate underlying structural problems.

- Cavity and Insulation: Inspect the cavity and insulation for any signs of moisture ingress or deterioration.

Roof

- Timber Rafters and Purlins: Examine the timber rafters and purlins for signs of rot or insect infestation.

- Concrete Tiles: Check the condition of the concrete tiles and ensure they are securely fixed.

Internal Walls

- Loadbearing and Non-loadbearing Partitions: Assess the condition of both loadbearing and non-loadbearing partitions for any signs of movement or cracking.

Floors

- Ground Floor: Inspect the concrete ground floor for any signs of settlement or cracking.

- First Floor: Check the T&G boarding and timber joists for signs of wear or damage.

Typical Defects Common in Cornish Unit Type II Houses

Corrosion of Steel Reinforcement

One of the most common defects in Cornish Unit Type II houses is the corrosion of the steel reinforcement within the PRC columns and panels. This corrosion can lead to cracking and spalling of the concrete, compromising the structural integrity of the property.

Moisture Ingress

Moisture ingress is another common issue, particularly in the external walls and roof. This can lead to dampness, mould growth, and deterioration of the building materials.

Timber Decay

Timber elements, such as the rafters, purlins, and joists, are susceptible to decay and insect infestation. This can weaken the structural components and lead to further issues if not addressed promptly.

Settlement and Cracking

Settlement and cracking can occur in the concrete ground floor and internal walls. These issues can be indicative of underlying structural problems and should be thoroughly investigated.

Conclusion

The Cornish Unit Type II house represents a significant chapter in the history of British housing. While these properties were designed to address the urgent housing needs of the mid-20th century, they are now known to have certain structural vulnerabilities. Buyers and investors should be aware of the potential risks and seek professional advice before purchasing a Cornish Unit Type II house.

At Flettons, we’re committed to safeguarding your investment. When considering a property purchase, trust our seasoned expertise to reveal any hidden threats. For a thorough building survey, get your instant quote through our quote calculator or reach out directly at 0203 691 0451. Your home’s safety is our top priority.