The Howells House: A Comprehensive Guide for Home Buyers and Investors

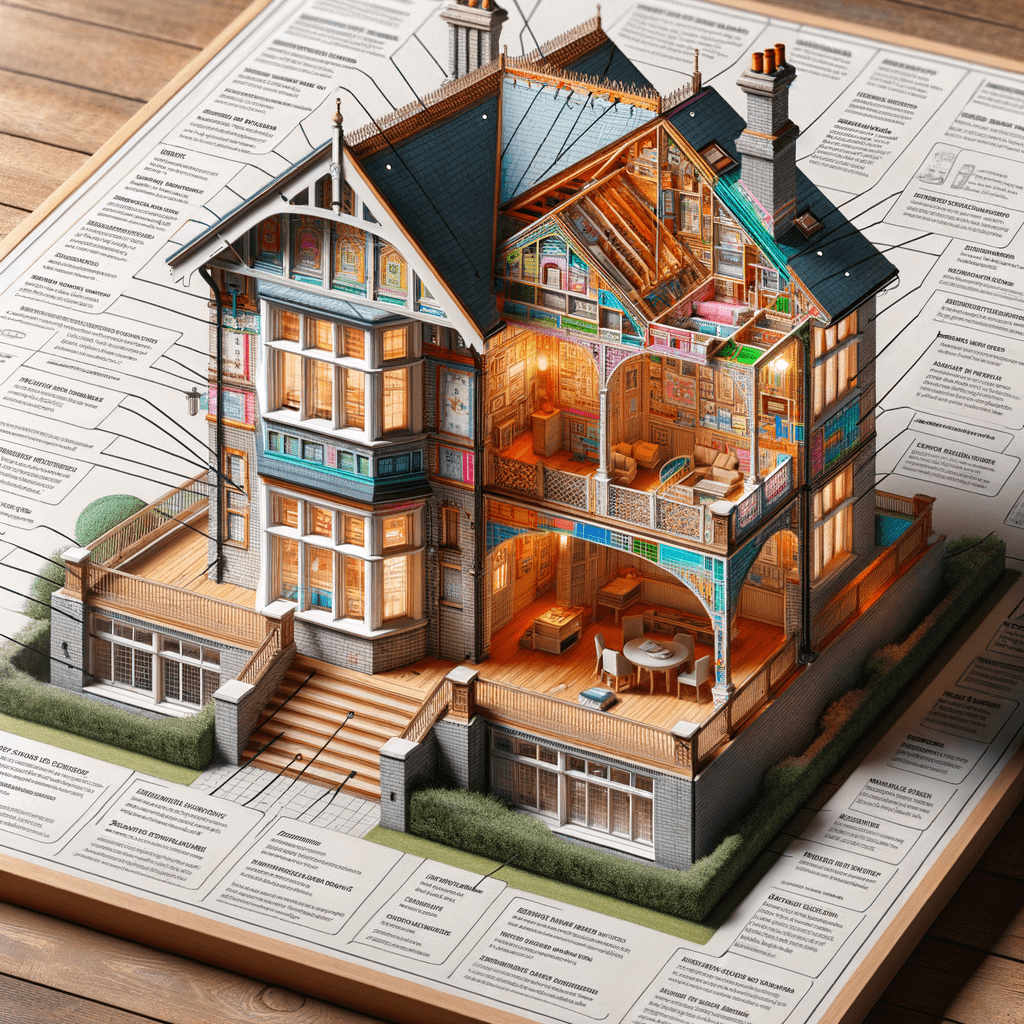

Overview of the Howells House

The Howells House, a distinctive property type in the UK, is a testament to early 20th-century construction ingenuity. Designed and manufactured by E O C Howells in the 1920s, these properties are primarily found as 2-storey semi-detached and terraced houses. They are known for their medium pitch hipped roofs covered with tiles or slates and external walls made of precast (PC) block columns, often rendered with roughcast. This article delves into the intricate details of the Howells House, providing valuable insights for home buyers and investors.

Historical Context and Manufacturing

Manufacturer and Designers

The Howells House was both designed and manufactured by E O C Howells, a prominent figure in the construction industry during the 1920s. The design and construction techniques employed in these houses were innovative for their time, reflecting the industrial advancements of the early 20th century.

Period Built

These houses were predominantly built in the 1920s, a period marked by a post-World War I housing boom. The need for affordable and quickly constructed homes led to the adoption of system-built properties like the Howells House.

Typical Locations

Howells Houses are typically found in suburban areas across the UK. They were part of the broader movement to provide quality housing for the growing urban population, often located in newly developed residential neighbourhoods.

Identification Characteristics

Structural Features

- 2-Storey Semi-Detached and Terraced Houses: These properties are commonly found as either semi-detached or terraced houses, providing a range of options for different family sizes and preferences.

- Medium Pitch Hipped Roof: The roofs are medium pitch and hipped, covered with either tiles or slates, contributing to their distinctive appearance.

- External Walls: The external walls are constructed using PC block columns, which are asymmetric at the corners, infilled with PC blocks or rendered with roughcast throughout.

- PC Ground Level Sill: A characteristic feature is the PC ground level sill, which adds to the structural integrity of the house.

- PRC Window Subframes and Canopy: The windows are framed with PRC subframes, and there is often a canopy over the front door.

- 2-Storey Gable Roof Bay: Some houses feature a 2-storey gable roof bay on the front elevation, adding to the architectural variety.

Typical Construction Details

Substructure

- Concrete Strip Footings: The foundation consists of concrete strip footings, providing a stable base for the structure.

- Concrete Under-Building: The under-building is also made of concrete, ensuring durability and strength.

- Slate DPC: A slate damp-proof course (DPC) is used to prevent moisture from rising through the walls.

External Walls

- Asymmetric Hollow PC Block Columns: The corners feature 8″ hollow PC block columns, which are asymmetric.

- Dense RC Infill: The intermediate columns are filled with dense reinforced concrete (RC).

- PC Blocks: The walls are constructed using 9″ x 18″ x 2″ PC blocks, with a 3″ cavity and additional 9″ x 18″ x 2″ PC blocks.

- Wall Ties and Reinforcement: Wall ties and mild steel reinforcement are used in the bed joints to enhance structural stability.

- RC Ring Beams: Reinforced concrete ring beams are placed at the first floor and eaves level, laced with column reinforcement.

Internal Walls and Partitions

- Concrete Slab Cavity Wall: The separating wall between properties is a concrete slab cavity wall.

- Clinker PC Block Partitions: Internal partitions are made of clinker PC blocks, providing sound insulation and fire resistance.

Floors

- Ground Floor: The ground floor is a concrete slab on timber block, ensuring a solid and stable surface.

- First Floor: The first floor consists of timber boarding on timber joists, supported by an RC ring beam.

Roof

- Timber Rafters and Purlins: The roof structure is made of timber rafters and purlins, covered with tiles or slates.

- Bitumen DPC: A bitumen damp-proof course is used to protect the roof structure from moisture.

Typical Hazards and Risks

Structural Issues

- Cracking: One of the most common issues is cracking between the concrete slab and PC block corner and intermediate columns. This can compromise the structural integrity of the house.

- Spalling: Spalling of exposed cantilevered ends to the first-floor PRC ceiling joists is another concern. This occurs when the concrete surface flakes off, exposing the steel reinforcement to corrosion.

Durability Concerns

- Corrosion of Steel in Concrete: The steel reinforcement within the concrete can corrode over time, especially if the concrete is not adequately protected from moisture. This can lead to significant structural damage.

- Carbonation: Carbonation of concrete, where carbon dioxide from the air reacts with the calcium hydroxide in the concrete, can reduce the alkalinity and lead to corrosion of the steel reinforcement.

Moisture Ingress

- Damp Issues: Despite the use of damp-proof courses, moisture ingress can still be a problem, particularly if the DPC is damaged or compromised.

Defective Premises Act Considerations

The Howells House is not typically classified as defective under the Defective Premises Act. However, due to the age and construction methods used, it is essential to conduct thorough inspections to identify any potential issues that could affect the safety and habitability of the property.

Inspection Guide for Surveyors

Pre-Inspection Preparation

Before conducting an inspection, it is crucial to gather as much information as possible about the property. This includes historical data, previous inspection reports, and any known issues.

External Inspection

- Roof: Check the condition of the tiles or slates, and inspect the timber rafters and purlins for signs of rot or damage.

- Walls: Look for cracks in the PC block columns and walls. Pay particular attention to the corners and intermediate columns.

- Windows and Doors: Inspect the PRC window subframes and door surrounds for signs of deterioration.

- Ground Level Sill: Ensure the PC ground level sill is intact and free from damage.

Internal Inspection

- Floors: Check the condition of the concrete ground floor and timber first floor. Look for signs of movement or damage.

- Walls and Partitions: Inspect the internal walls and partitions for cracks or other signs of structural issues.

- Ceilings: Although the ceiling construction is not well-documented, look for any signs of sagging or damage.

Structural Integrity

- Reinforcement Corrosion: Use a cover meter to detect the depth of concrete cover over the reinforcement. Check for signs of corrosion, particularly in areas where spalling is evident.

- Carbonation Depth: Conduct tests to determine the depth of carbonation in the concrete. This can help assess the risk of reinforcement corrosion.

Moisture and Damp

- Damp-Proof Course: Check the condition of the slate and bitumen DPCs. Look for signs of rising damp or moisture ingress.

- Ventilation: Ensure the property has adequate ventilation to prevent condensation and damp issues.

Typical Defects and Maintenance

Common Defects

- Cracking: As mentioned earlier, cracking is a common issue in Howells Houses. Regular monitoring and repair of cracks are essential to maintain structural integrity.

- Spalling: Addressing spalling promptly can prevent further damage to the concrete and reinforcement.

- Damp and Moisture: Regular maintenance of the DPC and ensuring proper drainage around the property can help mitigate damp issues.

Maintenance Tips

- Regular Inspections: Conduct regular inspections to identify and address issues early.

- Reinforcement Protection: Apply protective coatings to exposed reinforcement to prevent corrosion.

- Moisture Control: Ensure proper ventilation and drainage to prevent moisture-related problems.

Variants of Howells Houses

External Wall Variants

- Rendered Walls: Some Howells Houses have external walls rendered with roughcast throughout.

- Gable Roof Bays: Variants with rendered eaves height gable window bays on the front elevation.

- PRC Blocks: External walls made of 3″ PRC blocks.

Structural Variants

- Concrete First Floor: Some variants feature a concrete first floor instead of timber.

- Concrete Staircase: Certain Howells Houses have a concrete staircase with concrete balustrades.

- Roof Construction: Variants with PRC first floor ceiling joists cantilevered out over the wall plate to support rafters, covered with slates.

Conclusion

The Howells House is a unique and historically significant property type in the UK. Understanding its construction details, typical hazards, and maintenance requirements is crucial for home buyers and investors. By conducting thorough inspections and addressing potential issues promptly, you can ensure the longevity and safety of these properties.

At Flettons, we’re committed to safeguarding your investment. When considering a property purchase, trust our seasoned expertise to reveal any hidden threats. For a thorough building survey, get your instant quote through our quote calculator or reach out directly at 0203 691 0451. Your home’s safety is our top priority.