The Reema Hollow Panel House: A Comprehensive Guide for Home Buyers and Investors

Historical Context and Manufacturing Background

The Reema Hollow Panel house, a notable example of post-war British architecture, was a product of necessity and innovation. Manufactured by Reema Ltd, these homes were constructed between 1945 and 1966, a period marked by a significant housing shortage in the UK. The urgency to provide affordable and quickly assembled homes led to the development of various system-built properties, with the Reema Hollow Panel house being one of the prominent types.

During this period, approximately 17,600 Reema Hollow Panel houses were built. These homes were primarily located in suburban areas and were designed to cater to the growing demand for residential properties. The Reema Hollow Panel house is also known by several alternative names, including Engineered Homes, Bourne, Nadder, Stour, and Wylye.

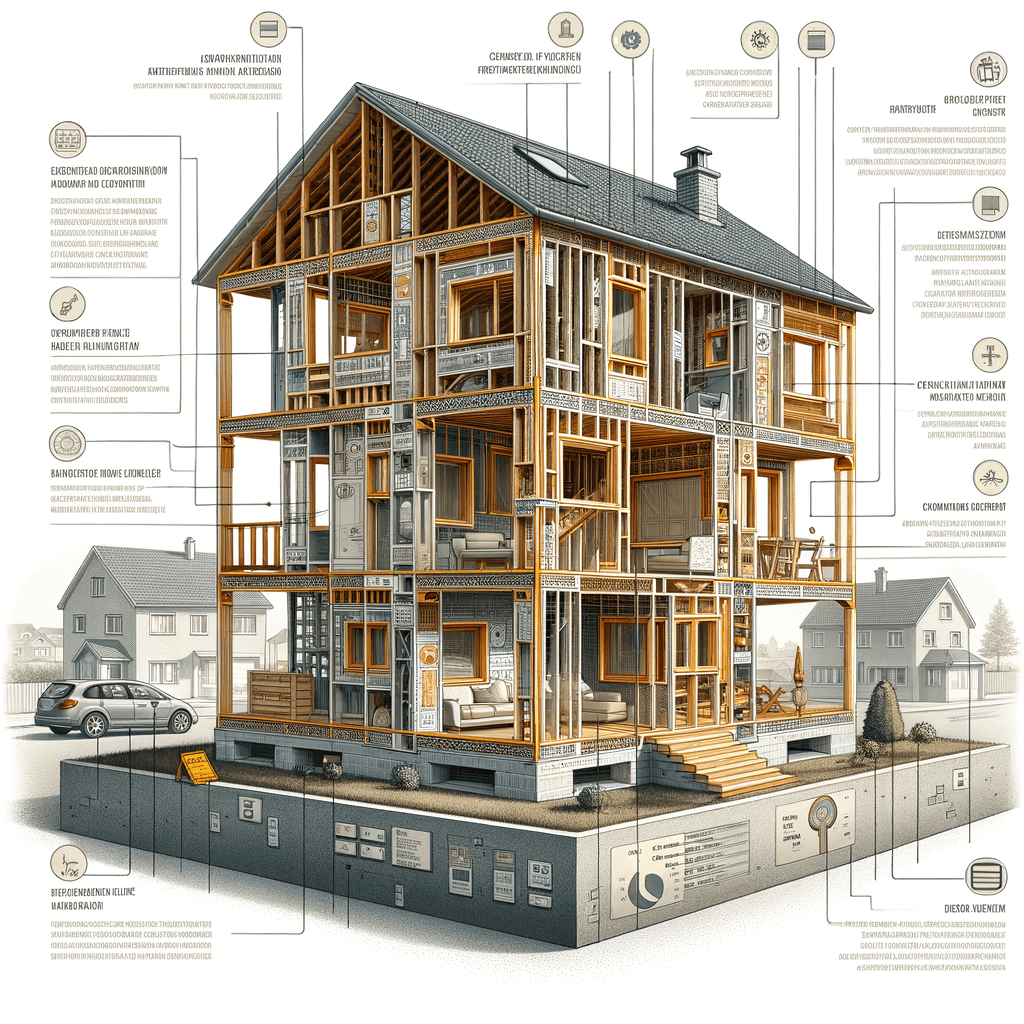

Design and Construction Characteristics

Architectural Features

Reema Hollow Panel houses are typically bungalows or two-storey semi-detached houses. They feature medium or shallow pitch hipped or gable roofs, which are covered with either concrete tiles or asbestos cement sheets. The external walls are constructed using storey-height exposed aggregate precast concrete (PC) panels or tile hanging, giving these homes a distinctive appearance.

Structural Components

Substructure

The substructure of Reema Hollow Panel houses consists of pad foundations located below the junction of each panel. These foundations support a concrete slab, which serves as the base for the entire structure.

External Walls

The external walls are made up of reinforced concrete (RC) columns and storey-height room-sized dense aggregate hollow precast concrete (PRC) panels with internal webs. These panels have a hollow core comprising a 1 1/2″ external leaf, a 6 1/2″ cavity, and a 1″ inner leaf lined with fibreboard. RC ring beams are cast into the trough-shaped panel heads at the first floor and eaves level, providing additional structural support. A timber wall plate is also used in the construction of the external walls.

Separating Walls and Partitions

The separating walls between different units are constructed using dense aggregate hollow PC panels. Internal partitions are also made of PC panels, with some non-loadbearing walls constructed using timber studs lined with plasterboard.

Floors

The ground floor is typically made of concrete, while the first floor consists of timber boarding on timber battens supported by 10 1/2″ hollow PC beams. This combination of materials provides a sturdy and durable flooring system.

Ceilings and Roof

The ceilings are constructed using plasterboard, while the roof is supported by timber rafters and purlins. The roofing material is either concrete tiles or asbestos cement sheets, depending on the specific design and construction period.

Typical Hazards and Risks

Carbonation and High Chloride Levels

One of the primary concerns with Reema Hollow Panel houses is the carbonation and high chloride levels in the hollow dense PC panels. Carbonation is a chemical reaction that occurs when carbon dioxide from the air penetrates the concrete, leading to a reduction in the pH level. This process can cause the steel reinforcement within the concrete to corrode, compromising the structural integrity of the panels.

Cracking and Spalling

Cracking and spalling are common issues in Reema Hollow Panel houses. Cracks can develop in the window and door reveals, sills, and floor beams. Spalling, which is the flaking or breaking off of concrete surfaces, can also occur, particularly in areas exposed to moisture and freeze-thaw cycles.

Pointing at Panel Joints

The pointing at panel joints, which is the mortar used to fill the gaps between the panels, can crack or become missing over time. This can lead to water ingress and further deterioration of the structure.

Defective Premises Act and Designation

Reema Hollow Panel houses are designated as defective under the Defective Premises Act. This designation means that these properties are recognized as having inherent structural defects that can affect their safety and habitability. As a result, potential buyers and investors should exercise caution and seek professional advice before purchasing a Reema Hollow Panel house.

Inspection Guide for Surveyors

When inspecting a Reema Hollow Panel house, surveyors should pay close attention to the following areas:

External Walls

- Check for Cracks and Spalling: Inspect the external walls for any signs of cracking or spalling, particularly around window and door reveals and sills.

- Examine the Pointing: Ensure that the pointing at panel joints is intact and not cracked or missing.

- Assess Carbonation and Chloride Levels: Use appropriate testing methods to assess the carbonation and chloride levels in the concrete panels.

Roof and Ceilings

- Inspect the Roof Covering: Check the condition of the concrete tiles or asbestos cement sheets, looking for any signs of damage or wear.

- Examine the Timber Rafters and Purlins: Ensure that the timber rafters and purlins are in good condition and free from rot or insect infestation.

- Check the Ceilings: Look for any signs of sagging or damage to the plasterboard ceilings.

Floors

- Inspect the Ground Floor: Check the concrete ground floor for any signs of cracking or movement.

- Examine the First Floor: Ensure that the timber boarding and battens are in good condition and that the hollow PC beams are free from cracks or other defects.

Internal Walls and Partitions

- Check for Cracks: Inspect the internal walls and partitions for any signs of cracking or movement.

- Assess the Condition of Non-Loadbearing Walls: Ensure that the timber stud walls are in good condition and that the plasterboard lining is intact.

Typical Defects and Maintenance Considerations

Carbonation and Chloride-Induced Corrosion

As mentioned earlier, carbonation and high chloride levels can lead to the corrosion of steel reinforcement within the concrete panels. Regular inspections and maintenance are essential to identify and address these issues before they compromise the structural integrity of the property.

Cracking and Spalling

Cracks and spalling should be repaired promptly to prevent further deterioration. This may involve patching the affected areas with suitable repair materials and ensuring that the underlying cause of the damage is addressed.

Pointing at Panel Joints

Maintaining the pointing at panel joints is crucial to prevent water ingress and subsequent damage. Regular inspections and repointing as necessary can help to keep the structure in good condition.

Roof and Ceiling Maintenance

The roof covering should be inspected regularly for signs of damage or wear, and any necessary repairs should be carried out promptly. Timber rafters and purlins should also be checked for signs of rot or insect infestation, and any affected areas should be treated or replaced as needed. Ceilings should be inspected for signs of sagging or damage, and repairs should be carried out as necessary.

Conclusion

The Reema Hollow Panel house represents a significant chapter in the history of British housing. While these homes were designed to address the urgent need for affordable housing in the post-war period, they come with their own set of challenges and risks. Potential buyers and investors should be aware of the typical hazards associated with these properties, including carbonation, high chloride levels, cracking, and spalling.

Given the designation of Reema Hollow Panel houses as defective under the Defective Premises Act, it is essential to seek professional advice and conduct thorough inspections before making a purchase. Regular maintenance and prompt repairs can help to mitigate some of the risks associated with these properties, ensuring that they remain safe and habitable for years to come.

At Flettons, we’re committed to safeguarding your investment. When considering a property purchase, trust our seasoned expertise to reveal any hidden threats. For a thorough building survey, get your instant quote through our quote calculator or reach out directly at 0203 691 0451. Your home’s safety is our top priority.