Understanding Frameform Houses: A Comprehensive Guide for UK Home Buyers and Investors

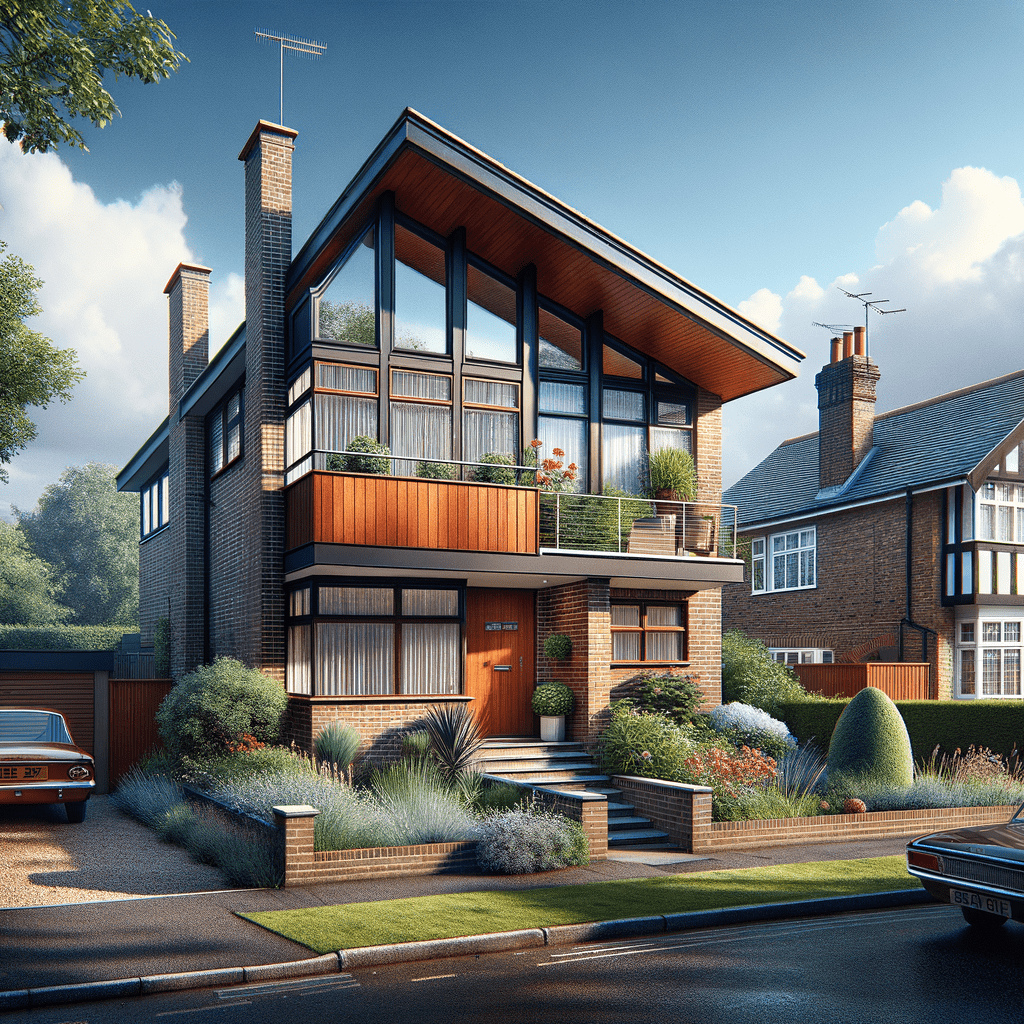

The Frameform House: An Overview

The Frameform house, a notable example of system-built properties, emerged during the mid-20th century as a response to the UK’s post-war housing demand. These homes, primarily constructed between 1965 and 1975, were the brainchild of James Riley and Associates, with designs crafted by D G Jones. Approximately 13,000 of these properties were built, predominantly featuring as bungalows and two-storey semi-detached or terraced houses. This article delves into the intricate details of Frameform houses, offering insights into their construction, typical characteristics, potential hazards, and inspection tips for prospective buyers and investors.

Historical Context and Manufacturing Details

The Frameform house was developed during a period when the UK faced a significant housing shortage. The need for rapid construction methods led to the adoption of system-built properties, which could be assembled quickly and efficiently. James Riley and Associates spearheaded the manufacturing of these homes, leveraging innovative design techniques by D G Jones. The Frameform houses were primarily constructed in urban and suburban areas, catering to the growing demand for affordable housing.

Typical Characteristics of Frameform Houses

Frameform houses are easily identifiable by their architectural features. They typically have a medium pitch gable or monopitch roof, covered with tiles, or a flat roof with asphalt or bituminous felt. The external walls are often clad with brick or render throughout, or feature a combination of brick on the lower levels and plywood with horizontal timber boarding or tile hanging above. Some dwellings also boast a cantilevered canopy over the front or rear door, adding a distinctive touch to their design.

Construction Details

Understanding the construction of Frameform houses is crucial for potential buyers and investors. These homes are built on concrete strip footings with brick under-building and a damp-proof course (DPC) to prevent moisture ingress. The external walls employ a platform frame construction, consisting of storey-height timber frame panels sheathed externally with plywood, overlaid with bituminous paper, and separately clad with brick. Internally, the walls are lined with plasterboard backed with a polyethylene vapour control layer, with mineral fibre insulation between the frame studs.

The separating walls are timber frame cavity walls, backed with plywood and lined with two layers of plasterboard. The partitions are timber stud lined with plasterboard, while the ground floor features tongue-and-groove boarding on timber joists. Upper floors are constructed with plywood on timber joists, and ceilings are finished with plasterboard. The roof structure comprises timber trusses, bituminous felt, and tiles, with mineral fibre insulation and a polyethylene vapour control layer at ceiling level.

Variants and Modifications

Over the years, several variants of the Frameform house have emerged, incorporating different materials and construction techniques. Some homes feature concrete edge beam and slab foundations, while others have external walls separately clad with rendered block throughout. The upper storeys of front and rear external walls may be clad with tile hanging or plywood on timber battens, or directly clad with horizontal timber boarding. Separating walls may be backed with diagonal timber bracing or asbestos cement sheets on one frame, with the opposite frame unbacked. Additionally, some Frameform houses have a concrete ground floor or a monopitch roof of timber trusses, bituminous felt, and tiles, while others have a flat roof of plywood decking and asphalt or bituminous felt.

Potential Hazards and Risks

While Frameform houses offer a unique architectural style and efficient construction, they are not without their potential hazards and risks. One common issue is bulging brickwork, which can occur due to moisture ingress or structural movement. Mortar bridging across the cavity can also lead to damp problems, compromising the integrity of the building. The omission of a bituminous breather membrane can exacerbate these issues, leading to further moisture-related problems.

Another concern is cladding overhanging the foundations, which can result in structural instability. Additionally, the use of asbestos cement sheets in some variants poses a health risk, as asbestos fibres can be released into the air if the material is disturbed. It is essential for buyers and investors to be aware of these potential hazards and to conduct thorough inspections before purchasing a Frameform house.

Defective Premises Act and Frameform Houses

The Defective Premises Act 1972 is a crucial piece of legislation that aims to protect homeowners from defects in their properties. Under this act, builders and developers are required to ensure that homes are constructed to a reasonable standard and are free from defects that could pose a risk to occupants. While Frameform houses are not inherently classified as defective under this act, the potential hazards and risks associated with their construction mean that buyers should exercise caution and conduct thorough inspections to identify any issues.

Inspection Tips for Frameform Houses

When inspecting a Frameform house, it is essential to pay close attention to specific areas that are prone to defects. Here are some key inspection tips to consider:

-

Check for Bulging Brickwork: Examine the external walls for any signs of bulging or movement, which could indicate structural issues or moisture ingress.

-

Inspect Mortar Joints: Look for mortar bridging across the cavity, as this can lead to damp problems and compromise the building’s integrity.

-

Assess Cladding and Foundations: Ensure that the cladding does not overhang the foundations, as this can result in structural instability.

-

Examine Roof and Insulation: Check the roof for any signs of damage or wear, and ensure that the insulation is intact and effective.

-

Identify Asbestos Materials: If the property features asbestos cement sheets, it is crucial to have them assessed by a professional to determine their condition and potential risk.

-

Evaluate the Damp-Proof Course: Ensure that the DPC is intact and functioning correctly to prevent moisture ingress.

-

Review the Vapour Control Layer: Check that the polyethylene vapour control layer is in place and effective, as this helps to prevent moisture-related issues.

-

Inspect the Timber Frame: Examine the timber frame for any signs of rot or decay, which could compromise the structural integrity of the building.

-

Assess the Insulation: Ensure that the mineral fibre insulation is in good condition and provides adequate thermal performance.

-

Check for Variants: Be aware of any variants in the construction, such as different cladding materials or roof types, and assess their condition and potential impact on the property.

Conclusion

Frameform houses represent a unique chapter in the UK’s architectural history, offering a blend of efficient construction and distinctive design. While these homes can provide an affordable and attractive option for buyers and investors, it is essential to be aware of the potential hazards and risks associated with their construction. By conducting thorough inspections and addressing any issues promptly, buyers can ensure that their Frameform house remains a safe and comfortable home for years to come.

At Flettons, we’re committed to safeguarding your investment. When considering a property purchase, trust our seasoned expertise to reveal any hidden threats. For a thorough building survey, get your instant quote through our quote calculator or reach out directly at 0203 691 0451. Your home’s safety is our top priority.