Unveiling the Argyll House: A Comprehensive Guide for Home Buyers and Investors

Historical Context and Background

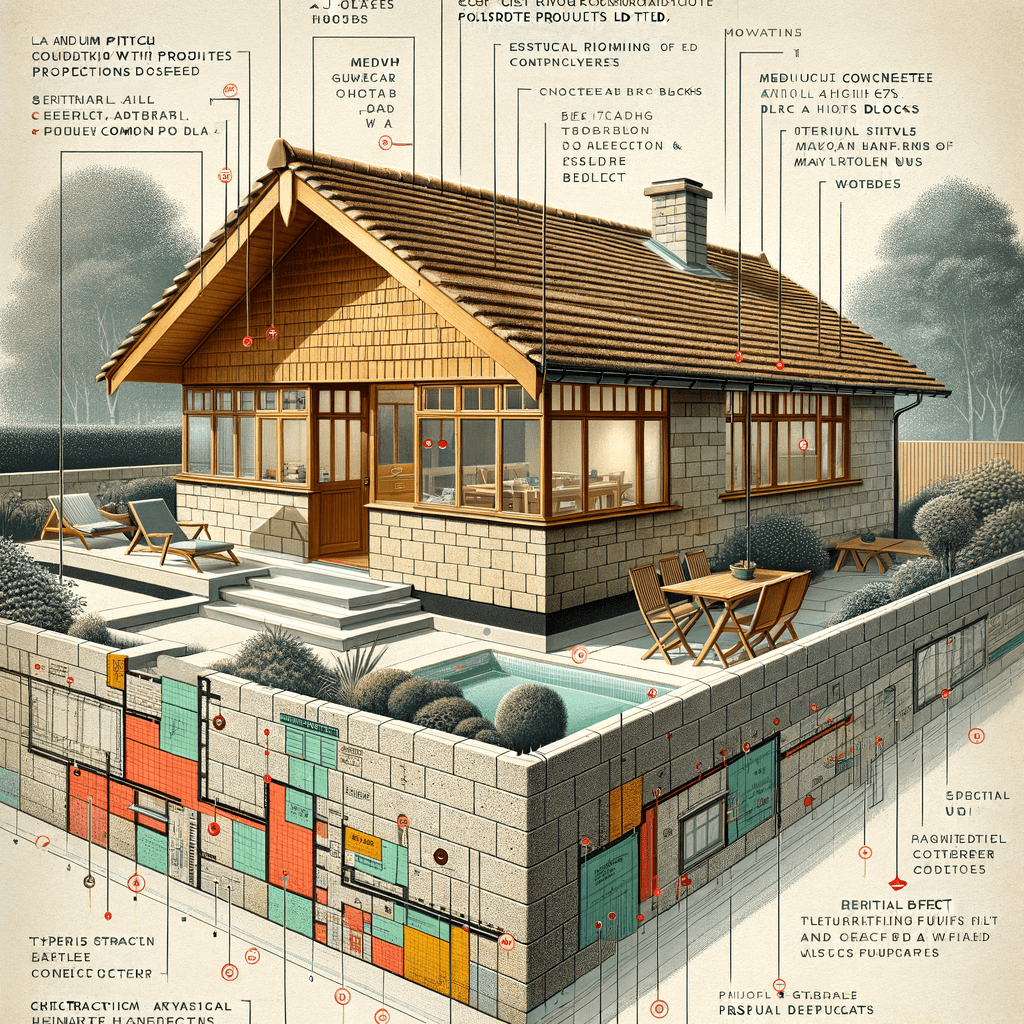

The Argyll house, a distinctive property type, was manufactured by Argyll Concrete Products Ltd. Designed by J. Thompson, these houses were constructed between 1947 and 1950. Only ten of these unique properties were built, making them a rare find in the UK housing market. Typically found as semi-detached and detached bungalows, the Argyll house stands out with its medium pitch gable roof covered with cedar shingles and external walls of exposed aggregate precast concrete (PC) blocks.

Manufacturers and Designers

Argyll Concrete Products Ltd, the manufacturer behind these houses, was known for its innovative use of precast concrete in residential construction. The designer, J. Thompson, played a crucial role in shaping the architectural and structural elements of the Argyll house. This collaboration resulted in a property that not only met the housing needs of the post-war era but also showcased advanced construction techniques of the time.

Typical Characteristics and Hazards

Identification Characteristics

The Argyll house can be identified by several key features:

– Semi-detached and detached bungalows: These properties are typically single-storey homes, either attached to another similar property or standing alone.

– Medium pitch gable roof: The roofs are covered with cedar shingles, providing a distinctive appearance.

– External walls: Made of exposed aggregate PC blocks, these walls are a defining characteristic of the Argyll house.

– PC window surrounds: The windows are set in precast concrete surrounds, adding to the structural integrity and aesthetic appeal.

Typical Hazards and Risks

While the Argyll house boasts several unique features, it is not without its hazards and risks. Some of the common issues associated with this property type include:

– Corrosion of steel in concrete: Over time, the steel reinforcement within the concrete can corrode, leading to structural weaknesses.

– Carbonation of concrete: This chemical process can reduce the alkalinity of the concrete, making the steel reinforcement more susceptible to corrosion.

– Maintenance challenges: The use of precast concrete blocks and other materials may require specialized maintenance and repair techniques.

Defective Premises Act Considerations

The Argyll house is not classified as defective under the Defective Premises Act. However, it is essential to conduct thorough inspections and assessments to ensure the property remains in good condition. Guidance on the inspection and assessment of reinforced concrete durability can be found in several BRE publications, including:

– Corrosion of steel in concrete (BRE Digest 444, Pts 1–3)

– Repair and maintenance of reinforced concrete (BR 254)

– Carbonation depths in structural-quality concrete (BR 19)

Inspection and Assessment Tools

When inspecting an Argyll house, several tools and techniques can be employed to assess its condition. These include:

– Visual inspection: Look for signs of cracking, spalling, or other damage to the concrete elements.

– Non-destructive testing: Techniques such as ultrasonic testing or ground-penetrating radar can help identify hidden defects.

– Carbonation testing: This can determine the depth of carbonation in the concrete and assess the risk of steel reinforcement corrosion.

– Moisture testing: Identifying areas of moisture ingress can help prevent further damage to the structure.

Typical Construction Elements

Substructure

The substructure of the Argyll house consists of concrete strip footings and concrete underbuilding. A damp-proof course (DPC) is also included to prevent moisture from rising through the structure.

External Walls

The external walls are constructed using precast reinforced concrete (PRC) base blocks. These blocks are 4 inches by 2.5 inches in size and are staggered within the width of the cavity. The walls also feature 5-inch by 2-inch cast in-situ or PRC head beams, which are tied to the columns by 0.5-inch diameter bolts cast into the column head. A timber wall plate is used to support the roof structure. The walls are further reinforced with 18-inch by 2.5-inch tongue and groove (T&G) exposed aggregate PC plinth units and 18-inch by 9-inch by 2.5-inch PC blocks. The cavity is filled with 2-inch vermiculite blocks, and copper tie wire is used to secure the face of the column to the bed joints of the blocks.

Separating Wall

The separating wall between properties is constructed using a PRC column and beam cavity wall, lined with lightweight concrete blocks. This provides both structural support and sound insulation between the properties.

Partitions

Internal partitions are made of lightweight concrete blocks, offering a balance of strength and ease of construction.

Ground Floor

The ground floor consists of timber boarding laid on a concrete base. This provides a stable and durable foundation for the living spaces.

Ceilings

Ceilings in the Argyll house are typically plastered on expanded metal lath, providing a smooth and durable finish.

Roof

The roof structure is made of timber trusses, covered with cedar shingles. This combination offers both strength and aesthetic appeal, with the cedar shingles providing a natural and attractive finish.

Typical Defects and Maintenance

Corrosion of Steel Reinforcement

One of the most common defects in Argyll houses is the corrosion of steel reinforcement within the concrete elements. This can lead to cracking, spalling, and ultimately structural failure if not addressed promptly. Regular inspections and maintenance are essential to identify and mitigate this issue.

Carbonation of Concrete

Carbonation is a chemical process that occurs when carbon dioxide from the air reacts with the calcium hydroxide in the concrete, forming calcium carbonate. This reduces the alkalinity of the concrete, making the steel reinforcement more susceptible to corrosion. Testing for carbonation depth and applying protective coatings can help prevent this issue.

Moisture Ingress

Moisture ingress can lead to a range of problems, including mould growth, timber decay, and damage to the concrete elements. Ensuring that the damp-proof course is intact and addressing any areas of water ingress promptly can help prevent these issues.

Cracking and Spalling

Cracking and spalling of the concrete elements can occur due to a range of factors, including thermal movement, shrinkage, and structural loading. Regular inspections and prompt repairs can help maintain the integrity of the structure.

Conclusion

The Argyll house, with its unique construction and historical significance, offers a distinctive option for home buyers and investors in the UK. While these properties come with their own set of challenges, understanding their construction and potential defects can help ensure they remain a valuable and attractive investment. Regular inspections, maintenance, and repairs are essential to preserving the structural integrity and aesthetic appeal of these homes.

At Flettons, we’re committed to safeguarding your investment. When considering a property purchase, trust our seasoned expertise to reveal any hidden threats. For a thorough building survey, get your instant quote through our quote calculator or reach out directly at 0203 691 0451. Your home’s safety is our top priority.