Unveiling the Argyll House: A Comprehensive Guide for Home Buyers and Investors

Introduction to the Argyll House

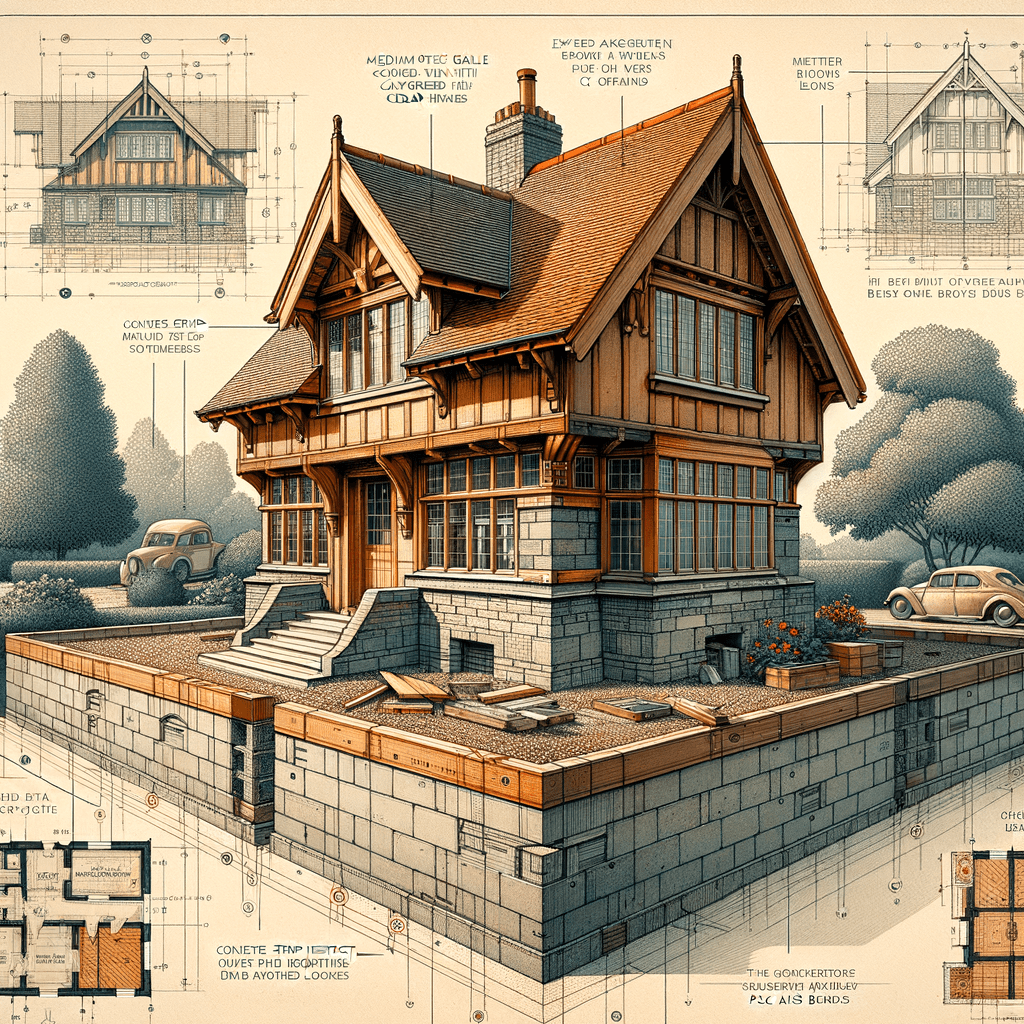

The Argyll house, a unique property type, holds a special place in the annals of British construction history. Built between 1947 and 1950, these homes were the brainchild of Argyll Concrete Products Ltd, with J. Thompson as the designer. Only ten of these properties were ever constructed, making them a rare find in today’s real estate market. This article aims to provide a detailed exploration of the Argyll house, covering its construction, typical characteristics, potential hazards, and inspection tips for prospective buyers and investors.

Historical Context and Manufacturer Background

The Post-War Construction Boom

The period immediately following World War II was marked by a significant housing shortage in the UK. The government and private sector responded with a surge in construction, often employing innovative methods and materials to expedite the process. The Argyll house is a product of this era, reflecting the ingenuity and resourcefulness of post-war Britain.

Argyll Concrete Products Ltd

Argyll Concrete Products Ltd was a prominent player in the post-war construction industry. Specialising in precast concrete (PC) products, the company was known for its innovative approach to building materials and techniques. The Argyll house, designed by J. Thompson, is a testament to their expertise in utilising PC blocks and other concrete elements to create durable and functional homes.

Typical Characteristics of the Argyll House

Architectural Features

The Argyll house is characterised by its semi-detached and detached bungalow designs. These homes feature a medium pitch gable roof covered with cedar shingles, giving them a distinctive appearance. The external walls are constructed from exposed aggregate PC blocks, providing both aesthetic appeal and structural integrity. PC window surrounds and steel windows are also typical features of these properties.

Construction Details

Substructure

The substructure of the Argyll house consists of concrete strip footings and concrete under-building. A damp-proof course (DPC) is included to prevent moisture ingress.

External Walls

The external walls are constructed using PRC base blocks and storey-height PC columns staggered within the width of the cavity. Cast in-situ or PRC head beams are tied to the columns with bolts cast into the column head. Timber wall plates and exposed aggregate PC plinth units complete the wall construction.

Separating Wall

The separating wall between properties is a PRC column and beam cavity wall lined with lightweight concrete blocks, ensuring both structural stability and sound insulation.

Partitions

Internal partitions are made from lightweight concrete blocks, providing a balance between strength and ease of construction.

Floors

The ground floor consists of timber boarding on concrete, while the first floor is not applicable as these are single-storey bungalows.

Ceilings

Ceilings are constructed using plaster on expanded metal lath, a common technique in mid-20th century construction.

Roof

The roof structure comprises timber trusses covered with cedar shingles, offering both durability and a traditional aesthetic.

Potential Hazards and Risks

Reinforced Concrete Durability

One of the primary concerns with the Argyll house is the durability of the reinforced concrete elements. Over time, concrete can suffer from various forms of degradation, including carbonation and chloride-induced corrosion. These issues can compromise the structural integrity of the property if not properly addressed.

Carbonation

Carbonation is a natural process where carbon dioxide from the air reacts with the calcium hydroxide in concrete to form calcium carbonate. This process reduces the alkalinity of the concrete, which can lead to the corrosion of embedded steel reinforcement. The depth of carbonation can be assessed using techniques outlined in BRE Digest 444 and BR 19.

Chloride-Induced Corrosion

Chloride ions, often from de-icing salts or marine environments, can penetrate concrete and cause corrosion of the steel reinforcement. This type of corrosion is particularly insidious as it can occur even in the absence of visible cracks or damage.

Maintenance and Repair

Regular maintenance and timely repairs are crucial to preserving the structural integrity of the Argyll house. Guidance on the repair and maintenance of reinforced concrete can be found in BR 254, which provides comprehensive information on addressing common issues and prolonging the lifespan of concrete structures.

Defective Premises Act and Argyll Houses

The Defective Premises Act 1972 imposes a duty on builders, developers, and landlords to ensure that properties are constructed and maintained to a reasonable standard. While the Argyll house is not specifically listed as defective under this Act, the potential issues with reinforced concrete durability mean that buyers and investors should exercise due diligence when considering these properties.

Inspection Tips for Surveyors

Pre-Inspection Preparation

Before conducting an inspection, it is essential to gather as much information as possible about the property. This includes reviewing historical records, previous survey reports, and any available maintenance documentation. Familiarising yourself with the typical construction details and potential hazards of the Argyll house will also help you conduct a thorough and efficient inspection.

External Inspection

Roof

Inspect the cedar shingles for signs of wear, damage, or moss growth. Check the timber trusses for any signs of rot or insect infestation. Ensure that the roof structure is sound and free from any significant defects.

Walls

Examine the external walls for cracks, spalling, or other signs of concrete degradation. Pay particular attention to the PC blocks and columns, as these are critical structural elements. Check for any signs of moisture ingress or damage to the DPC.

Windows and Doors

Inspect the PC window surrounds and steel windows for signs of corrosion, damage, or poor fitting. Ensure that all windows and doors are functional and provide adequate security and insulation.

Internal Inspection

Floors

Check the timber boarding on the ground floor for signs of wear, damage, or moisture ingress. Ensure that the floor is level and free from any significant defects.

Walls and Partitions

Examine the internal walls and partitions for cracks, damage, or signs of movement. Pay particular attention to the PRC column and beam cavity wall, as this is a critical structural element.

Ceilings

Inspect the plaster on expanded metal lath ceilings for signs of cracking, sagging, or water damage. Ensure that the ceilings are in good condition and free from any significant defects.

Structural Elements

Columns and Beams

Check the PRC columns and beams for signs of corrosion, cracking, or other forms of degradation. Pay particular attention to the connections between columns and beams, as these are critical points of structural integrity.

Concrete Elements

Assess the condition of all concrete elements, including the substructure, external walls, and separating wall. Look for signs of carbonation, chloride-induced corrosion, or other forms of concrete degradation.

Specialist Testing

In some cases, it may be necessary to conduct specialist testing to assess the condition of the reinforced concrete elements. This can include techniques such as carbonation depth testing, chloride content analysis, and non-destructive testing methods. Engaging a specialist in reinforced concrete assessment can provide valuable insights into the condition of the property and help identify any necessary repairs or maintenance.

Typical Defects in Argyll Houses

Concrete Degradation

As previously mentioned, concrete degradation is a common issue in Argyll houses. This can manifest as cracking, spalling, or delamination of the concrete elements. Regular maintenance and timely repairs are essential to address these issues and prevent further deterioration.

Corrosion of Steel Reinforcement

Corrosion of the steel reinforcement is another common defect in Argyll houses. This can be caused by carbonation, chloride ingress, or other factors. Corrosion can lead to a loss of structural integrity and should be addressed promptly through appropriate repair methods.

Moisture Ingress

Moisture ingress can occur through various pathways, including the roof, walls, and substructure. This can lead to issues such as rot, mould growth, and damage to internal finishes. Ensuring that the DPC is intact and addressing any sources of moisture ingress is crucial to maintaining the condition of the property.

Timber Decay

Timber elements, such as the roof trusses and wall plates, can be susceptible to decay if exposed to moisture. Regular inspections and maintenance are essential to identify and address any issues with timber decay.

Conclusion

The Argyll house is a unique and historically significant property type that offers both charm and potential challenges for home buyers and investors. Understanding the typical characteristics, potential hazards, and common defects of these properties is essential for making informed decisions and ensuring the long-term durability of the investment. By following the inspection tips and maintenance guidelines provided in this article, buyers and investors can confidently navigate the complexities of owning an Argyll house.

At Flettons, we’re committed to safeguarding your investment. When considering a property purchase, trust our seasoned expertise to reveal any hidden threats. For a thorough building survey, get your instant quote through our quote calculator or reach out directly at 0203 691 0451. Your home’s safety is our top priority.